The Impact of Maintenance Management Software on Operational Efficiency

For small to medium-sized businesses, achieving operational efficiency requires a substantial change in managing your assets. It’s about streamlining costs, employee efforts, and reducing time required to execute. The key to achieving operational efficiency is eliminating processes that create redundancy and waste. What powers that? Maintenance management software.

Inventory management, resource utilization, and production are all facts of your business that can fall to the wayside without proper direction and management. Maintenance management is your best resource for maintaining control, protecting your assets, and prolonging the lifespan of your business. Here’s how it can help you improve your business’s operations.

How Does Maintenance Management Work?

Maintenance management is all about your business operating smoothly and efficiently. Maintenance strategies can be used to inform key stakeholders how to complete tasks, whenever failures occur, and track tasks over time to improve productivity.

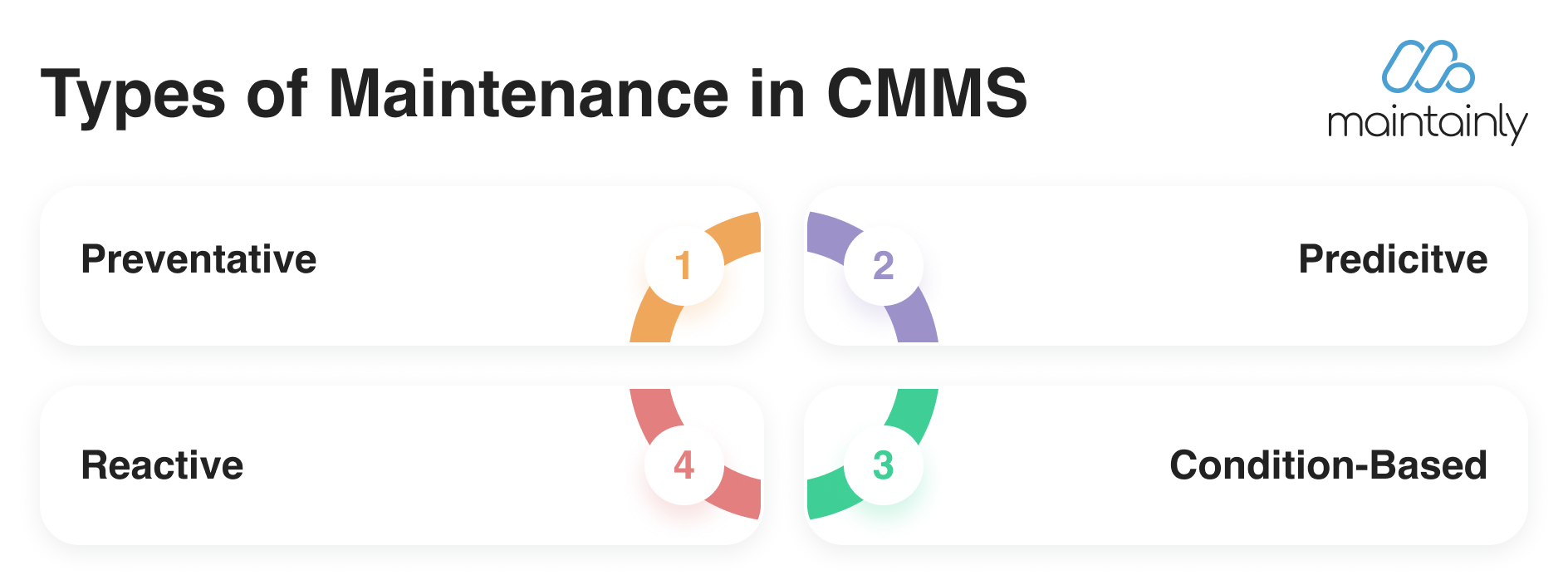

Preventative Maintenance

This strategy uses time-based scheduling and data analytics to identify potential issues or breakdowns in equipment. It’s a proactive approach aimed at helping organizations assess the reliability of their infrastructure and implement solutions to minimize risks. Some ways that preventative maintenance is used include routine inspections, maintenance task scheduling, and interval meetings with maintenance crews.

Predictive Maintenance

Predictive Maintenance

While preventative maintenance handles routine inspections and replacements, predictive maintenance notifies you beforehand through data collection. This strategy uses technologies such as automation, business analytics, cloud computing, and AI-machine learning to offer predictive data results. With this data, businesses can improve their service delivery, create room for flexibility in asset management, and improve their operations over time.

Predictive maintenance aims to continuously extend their assets’ lifespan and detect warning signs before any failures occur. Predictive maintenance is often combined with preventative measures to ensure all your assets maintain good working order and help avoid breakdowns.

Condition-Based Maintenance

Condition-based maintenance works to collect the health data of your assets and equipment. It operates as the intermediary, providing you with the immediate condition of your assets as data. Through this gathered data, you’ll be able to make rapid decisions about when maintenance is needed. While this strategy is only performed when it’s needed, it’s used as an immediate preventative for the onset of equipment failure.

Some examples of condition-based maintenance include attaching sensors to equipment for root-based analysis, where the sensors track temperature levels, vibration levels, and other factors that may indicate potential failure in the future.

Reactive Maintenance

Reactive maintenance happens once your assets have reached the point of failure. It only occurs when the asset experiences failure. While this strategy allows you to utilize your assets to their maximum capacity, it’s only beneficial if the repair costs are lower than the production value you receive.

In most cases, reactive or run-to-failure maintenance causes larger financial burdens on an organization with production slowing down or stopping. While capable of handling emergencies, it often leads to treating the symptoms rather than the causes of the problem itself.

Which Maintenance Strategy is Best For Operational Efficiency?

Which Maintenance Strategy is Best For Operational Efficiency?

Moving away from reactive measures is the key to achieving operational efficiency. Reactive measures can create massive financial problems and reduced efficiencies for your business down the line. If you’re working to improve operational efficiency, the goal for any business is to shift from reactive to proactive measures. By implementing proactive measures, such as predictive or preventive maintenance, you’ll be able to better utilize your assets, save money, and increase your company’s output.

A key aspect of maintenance management is being selective about your strategies. While most strategies provide a glance at how maintenance management can be done, it takes the right tools to monitor performance, identify infrastructure waste, and create benchmarks to track where your business stands against competition. If your maintenance management strategies are lacking, then it’s time to review and update them with newer, better technologies.

How CMMS Leverages Proactive Maintenance For Efficiency

CMMS is the game-changer for maintenance management. As a software solution designed to streamline maintenance operations, CMMS is software that creates a centralized hub for managing all aspects of your business. From managing orders and inventory to performing preventative maintenance tasks, CMMS platforms offer a valuable interface for you to engage with your business’s systems and improve them over time.

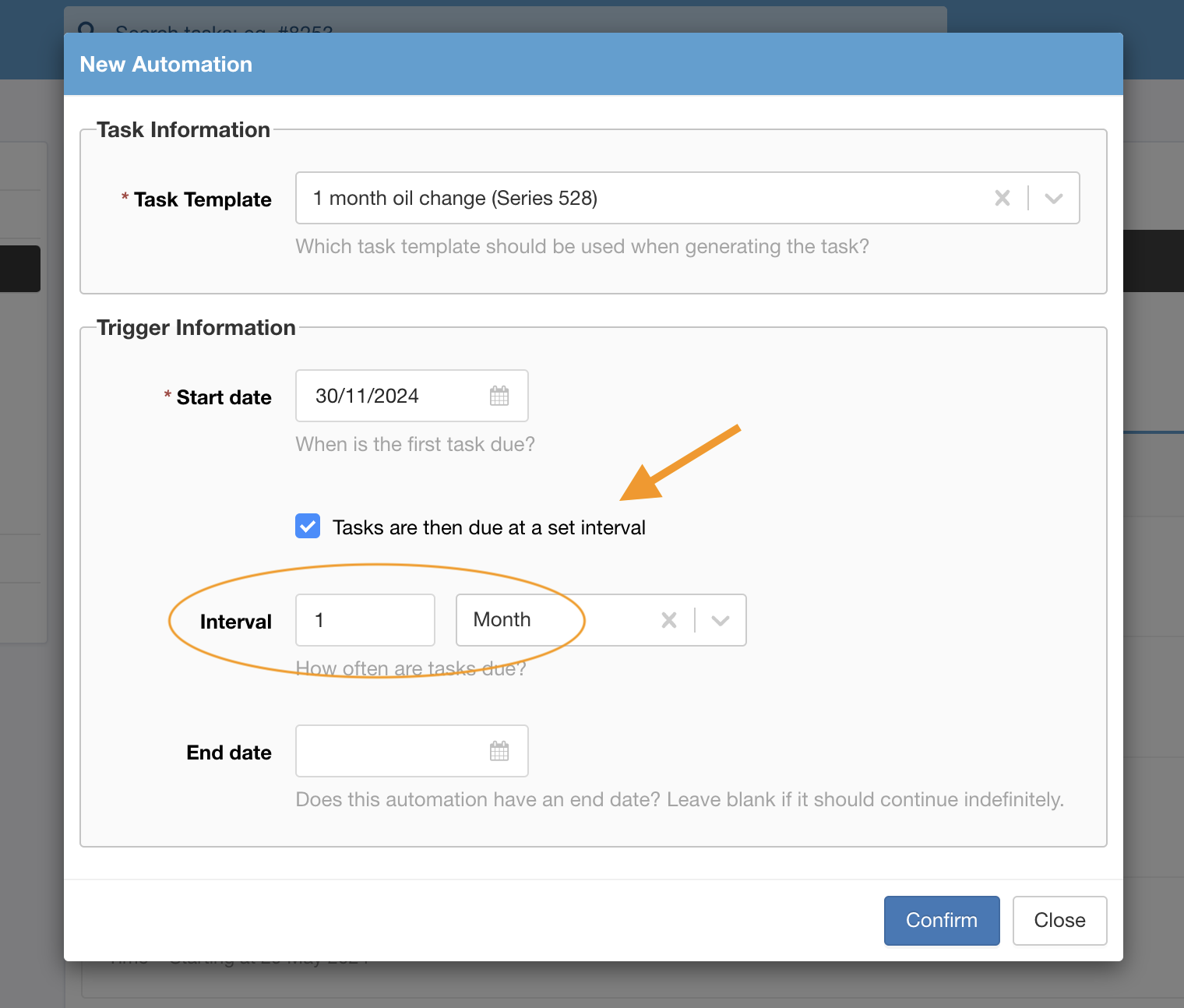

CMMS platforms excel in preventative and predictive maintenance, offering a variety of management tools to help businesses implement these strategies more effectively. These tools include:

Work Order Tracking: Through CMMS, tracking work orders can be integrated into a seamless process. CMMS platforms that feature work tracking systems can help you manage work tasks when they’re created right, delegated to team members, and tracked until they’re completed.

Optimizing Scheduled Maintenance: CMMS offers the ability to schedule preventative maintenance tasks, such as routine checkups and repairs. This system allows you to protect your assets and allocate resources for better maintenance budgeting. By offering a consistent tracking system, you can ensure equipment repairs and prevent the onset of costly, reactive measures.

Data-Driven Analytics: In predictive management, data-driven analytics is necessary. CMMS can provide systems to track data over time, giving you and your team insights into trends, production outputs, possible equipment failures, and other facets to ensure better efficiency.

Centralized Asset Hub: Every aspect that needs to be managed can be tracked within one centralized hub. Through CMMS, it provides a storage space for all of your data-related resources and consolidates it into an easily accessible platform. More importantly, CMMS doesn’t need a learning curve to use effectively, so it can be leveraged to its full potential for your maintenance strategies.

Start Your Free Maintainly CMMS Trail Today

At Maintainly, our CMMS platform can become your go-to asset for maintaining maintenance operations. As a versatile solution to maintenance management, our software program can contribute to a more efficient, productive environment, improving your business's bottom line across any industry. Maintainly makes CMMS management simple, refreshing, and easy to execute. If you want to improve your output, try Maintainly CMMS free for 14 days and see how we differ from your usual CMMS system.