Mobile menu

Maintenance Management

Whether you're a facilities manager, maintenance professional, or business owner, our expert-curated content offers valuable insights to optimize workflows, reduce downtime, and maximize asset performance. Stay informed with the latest trends and practical tips to make the most of maintenance management software.

← Back

Preventive vs Predictive Maintenance: Key Differences Explained

Preventive and predictive maintenance take very different approaches to keeping equipment running. This guide breaks down the key differences and helps you decide which strategy, or combination, fits your operation.

View article →

Small Fleet Maintenance: A Practical Guide for 5-25 Vehicles

Fleet maintenance strategies designed for small businesses with 5-25 vehicles. Learn how to build a maintenance program that works without dedicated mechanics or enterprise software budgets.

View article →

Using Asset QR Codes to Speed Up Maintenance Tasks

Maintenance teams are under constant pressure to do more with less. Assets are spread across buildings or sites, response times matter, and small delays can quickly turn into downtime, complaints, or safety risks. In this environment, even saving a few minutes per task can add up to a major efficiency gain over time.

View article →

Fleet Maintenance KPIs: 12 Metrics That Actually Matter

Learn the essential fleet maintenance KPIs that help you reduce costs, improve uptime, and make data-driven decisions. Includes formulas, benchmarks, and practical tips for tracking each metric.

View article →

Fleet Maintenance Checklist: The Complete Guide for Vehicle Fleets

A comprehensive fleet maintenance checklist covering daily, weekly, monthly, and annual inspections. Includes checklists for trucks, vans, service vehicles, and heavy equipment to reduce breakdowns and extend vehicle life.

View article →

Top Maintenance Software for Food & Beverage Manufacturing Operations (2026 Guide)

This guide compares top maintenance software options, with special focus on solutions like Maintainly that are well-suited to small and mid-size manufacturing teams seeking fast setup and easy adoption.

View article →

Managing Volunteer Maintenance Teams at Churches: A Complete Guide

How to build, organize, and retain an effective volunteer maintenance team at your church. Covers recruitment, training, task assignment, communication, and tools to keep volunteers engaged and facilities well-maintained.

View article →

Tools to Manage Hotel HVAC, Plumbing, and Electrical Systems

Running a hotel is a 24/7 operation. Guests expect comfortable rooms, reliable hot water, working lights, and quiet, efficient climate control at all times. Behind the scenes, that comfort depends on three critical systems: HVAC, plumbing, and electrical infrastructure.

View article →

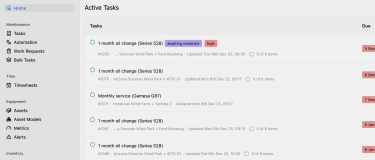

A Complete Breakdown of the New UI Features and Functional Improvements in Maintainly CMMS

Modern maintenance teams don’t just need more features. They need software that feels fast, clear, and EASY TO USE every single day. That’s exactly why Maintainly rolled out its brand-new UI. It is a functional upgrade designed around how maintenance work actually happens.

View article →

How Agricultural Maintenance Software Helps Farmers Cut Costs, Increase Uptime, and Streamline Workflows

Before sunrise, a farmer walks the field to check the irrigation lines. The soil is ready, the weather looks right, and the plan for the day is clear.

View article →