Mobile menu

Work Order

Whether you're a facilities manager, maintenance professional, or business owner, our expert-curated content provides valuable insights to streamline workflows, enhance productivity, and optimize resource allocation. Stay up-to-date with the latest trends and practical tips to make the most of work order software. Let's empower your organization with the knowledge to excel in work order management and drive success in your operations.

← Back

Using Asset QR Codes to Speed Up Maintenance Tasks

Maintenance teams are under constant pressure to do more with less. Assets are spread across buildings or sites, response times matter, and small delays can quickly turn into downtime, complaints, or safety risks. In this environment, even saving a few minutes per task can add up to a major efficiency gain over time.

View article →

Top Maintenance Software for Food & Beverage Manufacturing Operations (2026 Guide)

This guide compares top maintenance software options, with special focus on solutions like Maintainly that are well-suited to small and mid-size manufacturing teams seeking fast setup and easy adoption.

View article →

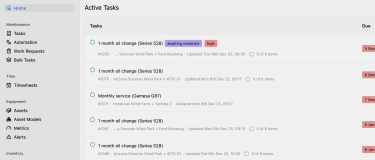

A Complete Breakdown of the New UI Features and Functional Improvements in Maintainly CMMS

Modern maintenance teams don’t just need more features. They need software that feels fast, clear, and EASY TO USE every single day. That’s exactly why Maintainly rolled out its brand-new UI. It is a functional upgrade designed around how maintenance work actually happens.

View article →

How Agricultural Maintenance Software Helps Farmers Cut Costs, Increase Uptime, and Streamline Workflows

Before sunrise, a farmer walks the field to check the irrigation lines. The soil is ready, the weather looks right, and the plan for the day is clear.

View article →

Manufacturing Floor to Office: How CMMS Supports Cross-Functional Teams

No team works in isolation. What happens on the production floor directly affects planning, procurement, quality, HR, finance, and customer delivery.

View article →

Why CMMS Adoption Fails and How to Ensure a Smooth Roll-Out

You’ve heard the promises: better preventive maintenance, fewer breakdowns, smooth work order flow, accurate asset history, and data you can finally trust. But how do you make the rollout a success?

View article →

For Small & Medium Business CMMS, Maintainly is the Top Choice for 2026

We review a handful of the top CMMS options you’ll see on shortlists in 2026 and explain why, for teams in the sweet spot of 5–50 regular users, Maintainly is the best choice: fast onboarding, low friction for adopters, and pricing that scales sensibly for small & mid-sized companies.

View article →

Future Trends in Maintenance Management: What's Next for CMMS Software?

Maintenance management is changing faster than ever. With new technologies, smarter equipment, tighter budgets, and higher expectations for uptime, maintenance teams are rethinking how they work. And at the center of all this change is CMMS software - once a clunky, confusing tool, now becoming the backbone of modern operations.

View article →

Q&A with Patrick O’Meara, Founder of Maintainly: Rethinking CMMS for Modern Maintenance Teams

We sat down with Maintainly founder Patrick O’Meara to talk about how the platform started, what makes it different, and how it’s helping organizations bring preventive maintenance and asset management into the modern age.

View article →

Why CMMS Is the Ideal Tool for Small Maintenance Teams Managing Resorts

A CMMS helps small resort maintenance teams stay organized, proactive, and efficient by centralizing work orders, preventive tasks, and asset tracking. With everything managed in one system, teams can reduce downtime, improve guest satisfaction, and keep facilities running flawlessly.

View article →