What Industries Benefit From CMMS?

Businesses of all sizes rely on CMMS for accurate asset management. If you have a large inventory, production equipment or a fleet of vehicles then you can benefit from CMMS.

How Does a CMMS Work?

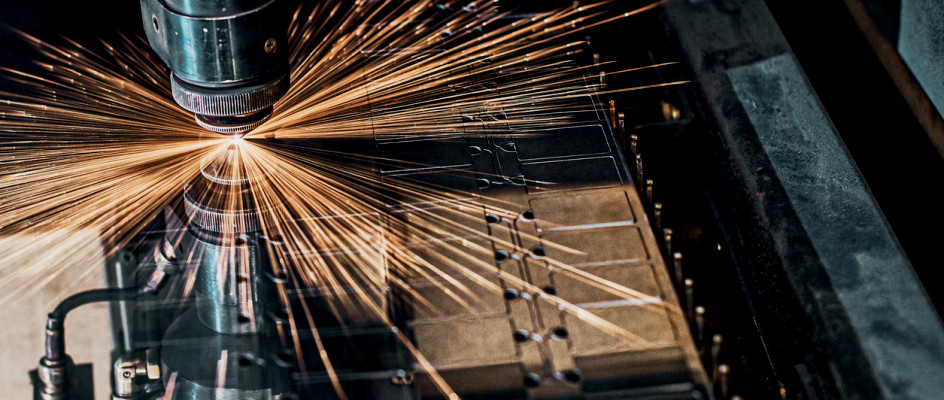

A CMMS centralizes information about your business inventory, specifically all of your assets and equipment. For example you own a fabrication machine that produces aluminum products for small engines a CMMS can track every detail including:

Purchase and Creation Date: Tracks when the piece was originally added to the inventory

Location and Description - Displays information about the asset’s current location and details about the asset itself. Model number, manufacturer, location of replacement parts

Identification and Warranty - Displays information about the manufacturer’s warranty and identification via barcodes or serial numbers. Instantly locate information for an upcoming repair or replacement

Lifespan and Maintenance History - All previous repairs and maintenance, scheduled tasks and everyone involved

Coverage, Depreciation, and Salvage Value - Shows information about insurance coverage and depreciation after purchase, as well as potential salvage value.

All of this information is helpful to improve operating efficiency. For example, you can authorize technicians to maintain equipment via work orders. The technicians can then refer to the asset’s age, maintenance history, SOPs, and other documentation. This helps minimize risks such as equipment-related errors or safety hazards. It also is useful to schedule upgrades and maintenance strategically so that production lines are not affected.

What Industries Use CMMS?

Many industries rely on CMMS software applications to maintain their assets. These industries typically demand specialized equipment or assets that need to be stored, tracked, and maintained.

Energy

Utility companies like power plants or water treatment plants use CMMS to keep their infrastructure up and running. Energy providers require constant uptime, necessitating regular preventive and corrective maintenance to address potential issues.

Energy companies and power plants are also subject to frequently changing regulations. Having a flexible CMMS that can update SOPs and reinvent maintenance strategies to maximize effectiveness (and thus profit) is essential to success. It can also ensure the right tools are on hand to avoid delayed repairs.

Transportation

The transportation industry has many logistical considerations. That includes moving different cargo to different locations for different purposes using different equipment.

Companies with vehicle, airline, or shipping services rely on fleet CMMS for maintaining their vehicles, to improve operational efficiency and safety. For fleet vehicles, downtime directly impacts profitability and operational efficiency. A CMMS can evaluate manufacturer-recommended repairs and schedule maintenance to reduce downtime and potentially dangerous breakdowns.

Manufacturing

Manufacturers often rely on specialized equipment to produce goods efficiently. Downtime on these machines can be devastating, so these industries leverage manufacturing CMMS to standardize repairs, track machines, and evaluate labor costs.

Construction

Companies invest millions into construction equipment each year. Machine failures pose safety hazards and leave workers unable to continue until repairs are complete. This also leaves the workers idle while the equipment is being repaired.

Maintaining and repairing this equipment is expensive and demands specialized knowledge, so companies rely on CMMS to establish SOPs and schedule work orders for preventive maintenance. It’s also useful to manage logistics.

Companies may need to transport equipment to and from work sites. A CMMS with real-time geolocation makes tracking equipment locations effortless.

Healthcare

Healthcare facilities use lots of specialized medical equipment. It’s important for patients that this equipment stays running and doesn’t malfunction. A CMMS can record key information about this equipment and schedule maintenance so that unexpected breakdowns don’t happen.

Creating checklists and SOPs through a CMMS can also make sure things are done properly, which is essential in an environment where all work must be up to legal codes.

Pharmaceutical

Pharmaceutical companies face ever-changing regulations. Regular maintenance helps companies stay competitive and relevant in light of changing consumer needs. Of course, poor maintenance procedures can lead to contamination, shortages, or harm to consumers.

A CMMS establishes SOPs to ensure proper equipment handling and maintenance while providing tools to create a robust audit trail. This is especially pertinent to pharmaceutical and medical industries since they are held to a rigorous auditing standard.

Do You Need a CMMS?

Ultimately, it’s your call whether or not to use a CMMS for maintenance procedures. Here are some reasons you may consider one:

You have lots of assets or equipment - If you find it hard to manage your business assets, you may consider a CMMS to keep track of everything.

You have specialized (expensive) equipment - Downtime for specialized equipment can be devastating to the bottom line. Consider a CMMS if your business relies on these machines having near-constant uptime.

You need SOPs - Standard Operating Procedures set the bar for quality and are prerequisites for certain certifications . If you have maintenance that must be done right every time, a CMMS can make sure your technicians are up to speed.

You need to scale your business - Scaling often means increasing inventory size or equipment complexity.

Consider Maintainly as Your CMMS!

If you need a reliable, intuitive, and effective CMMS, consider Maintainly. With this advanced maintenance system software package, you can create hierarchies of assets, set up work orders, and schedule preventive maintenance to keep your equipment in optimal condition.

Less than 2% of customers needed additional support after onboarding, which means you can start inputting your first asset in minutes. Plus, with our suite of tools, you can mix ‘n’ match to get the price you want—scaled whenever it’s best for you. If you want to learn more, you can register for a free trial today!