Mobile menu

CMMS for manufacturing running in minutes, not months

The leading computerized maintenance management system for manufacturing teams who need reliability, mobile access, and preventive maintenance scheduling - without the complexity of legacy systems. Easily manage work orders, PM schedules, and asset tracking for manufacturers, all in one place with purpose-built plant maintenance software.

Try it for free

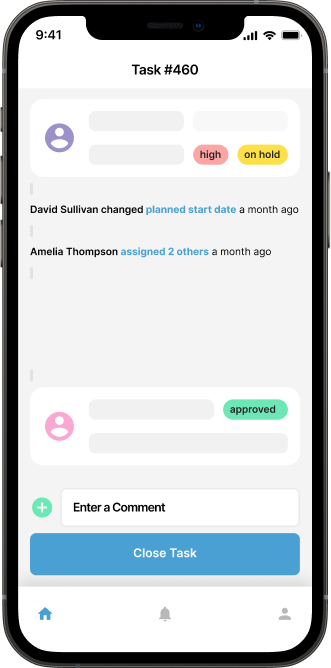

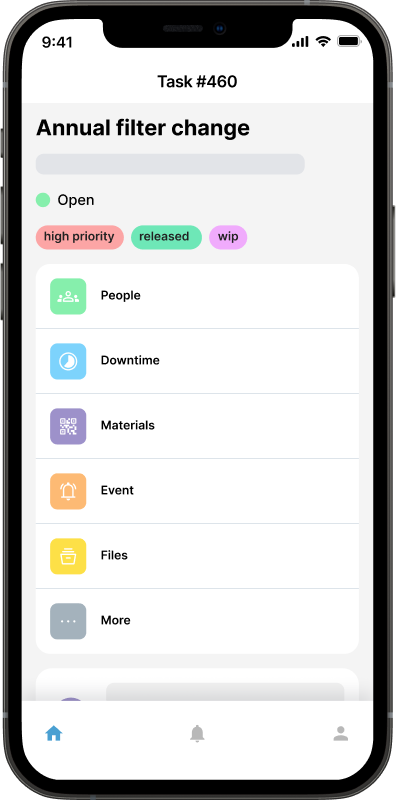

Manufacturing work order tools

Mobile work orders that let you document everything: photos, meter readings, file uploads, downtime logs and key metrics for both preventive and reactive maintenance tasks.

- Scan asset QR codes on machines to create or view work orders

- Reactive or automated preventive maintenance scheduling tasks

- Trigger maintenance when by taking regular meter readings

- Manage maintenance requests from staff

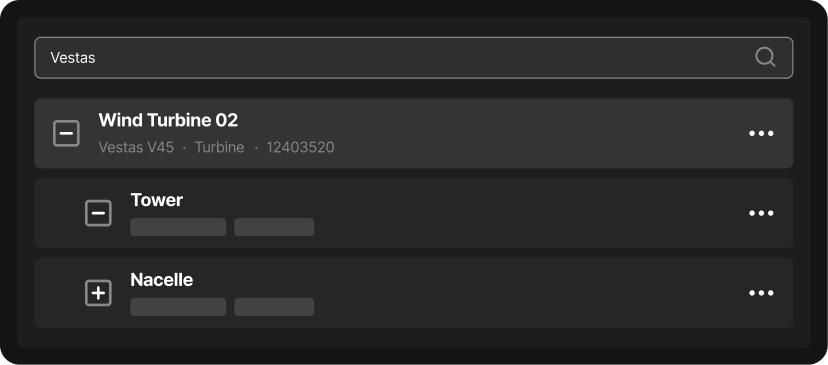

Total visibility over your plant floor

Maintainly's asset tracking for manufacturers makes it easy to organize complex equipment hierarchies and trace full maintenance history - perfect for dynamic manufacturing environments where precision matters.

- Build flexible asset hierarchies that match your production lines

- Use mobile-friendly QR codes to scan and update machines on the go

- Maintain a full audit trail of maintenance actions and equipment changes

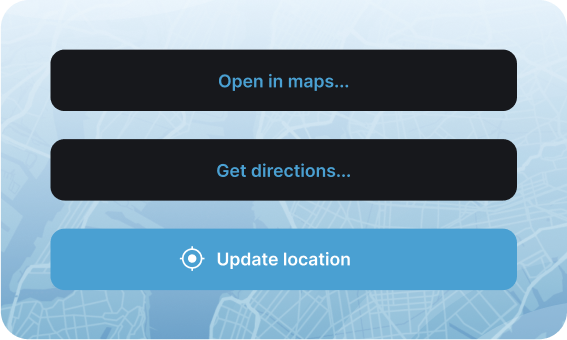

- Your manufacturing tracking software and maintenance hub in one - QR scans, audit trails, and geolocation all connected.

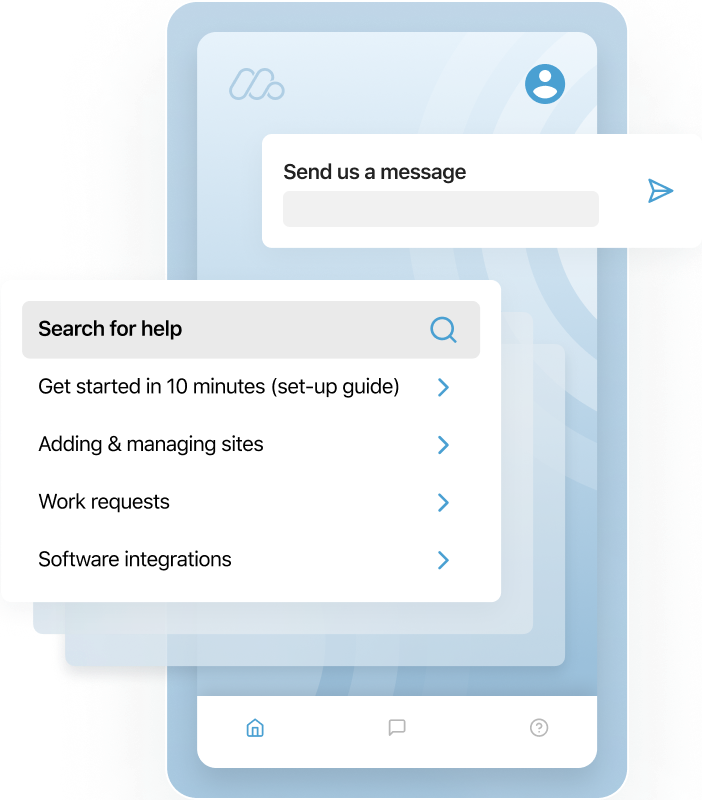

Legacy CMMS slowing down your factory floor?

Say goodbye to clunky systems and long onboarding. Maintainly is the best CMMS for manufacturing facilities that want a flexible, intuitive platform — one that fits seamlessly into fast-paced environments without the enterprise price tag.

- Get up and running in minutes - not weeks or months

- Onboarding support and setup help is included

- So intuitive that less than 2% of users ever request training

- Modular design - pay only for what you need & scale when needed.

Built for manufacturing

maintenance teams

A robust CMMS toolkit designed to streamline how you request, schedule, complete, and document maintenance on the plant floor. Maintainly helps you minimize downtime, extend asset life, and stay audit-ready with complete service histories - including part usage, technician notes, breakdown causes, and equipment photos - all in one place.

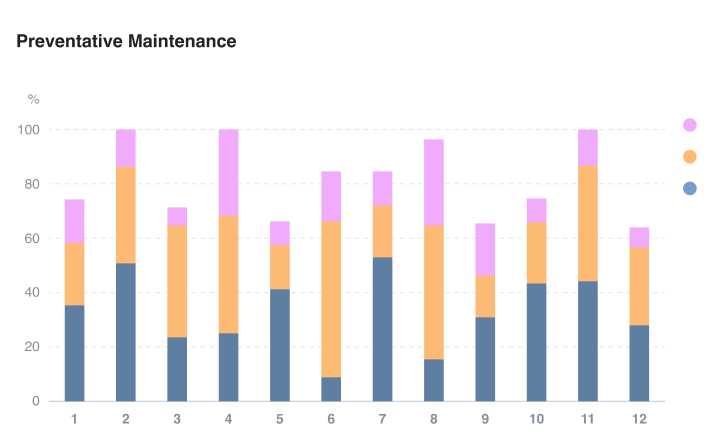

All Manufacturing Environments

From food and pharma to plastics, automotive, and more, Maintainly fits your operation. Automate PMs by date or runtime to never miss a lube, calibration, or inspection.

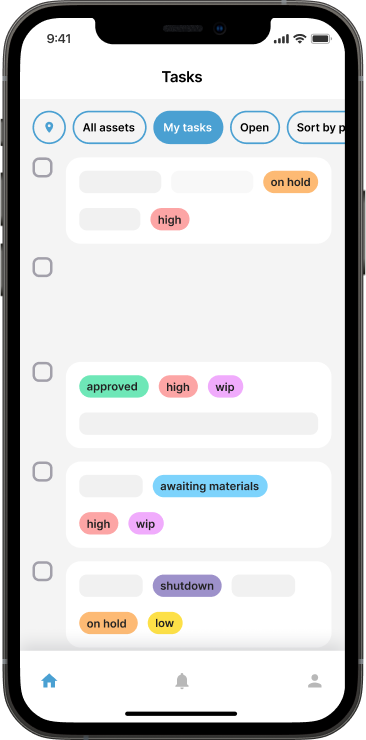

Downtime & Corrective Work

Capture breakdowns as they happen. Log failure codes, assign repairs, and track resolution steps - all from the factory floor via mobile. Push notifications keep technicians in the loop.

Mobile Work Orders

Equip your technicians with a powerful mobile CMMS. Scan equipment barcodes, log repairs, attach photos, and update job status in real-time - no need to return to a desk.

Maintenance Requests

Let operators and line supervisors submit maintenance issues easily, without needing system access. Keep them informed automatically with request status updates.

Whether you’re managing individual machines, entire production lines, or facility-wide systems, Maintainly gives you the flexibility to build and manage equipment hierarchies that match your manufacturing environment. Start from a flat list or import complex setups in minutes.

Shop-Floor Ready QR Labels

Tag machines and line assets with QR labels to instantly access maintenance history, log faults, or create new work orders from the Maintainly mobile app - right on the factory floor.

Scalable Asset Hierarchy

Build a multi-level hierarchy for everything from entire production lines down to motors, gearboxes, and valves. Ideal for tracking maintenance on critical components across complex systems.

Maintenance Audit Trail

Track every repair, inspection, and replacement part used on each asset. Detailed maintenance logs help you stay compliant and enable root cause analysis for recurring failures.

Asset Movement & Location

Keep tabs on movable or shared assets such as tooling, forklifts, or mobile generators. Use location filters to assign or prioritize work based on asset whereabouts.

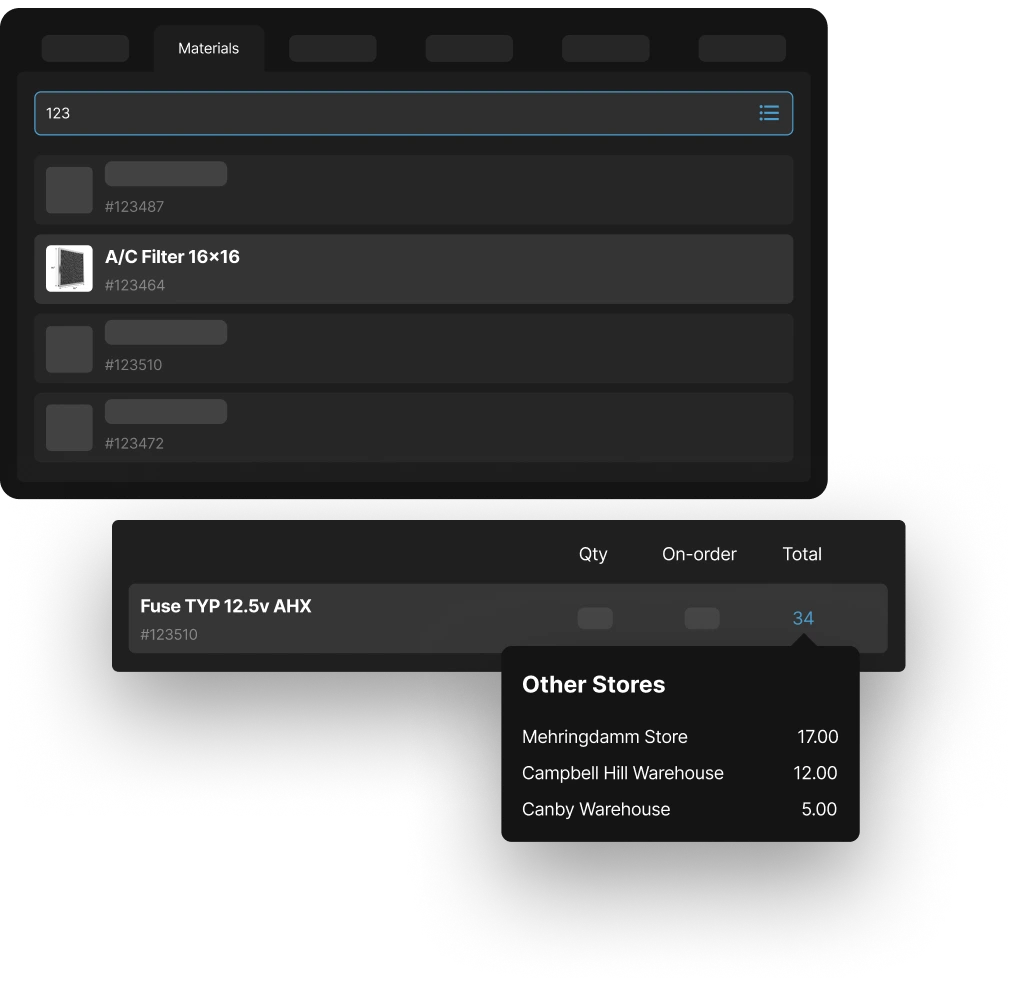

Reduce downtime and avoid stockouts by accurately tracking spare parts and materials across all your warehouses or storage areas. Maintainly's spare parts inventory management tools are built for maintenance - not procurement - so your team stays focused on uptime and readiness.

Spare Parts Linked to Work Orders

Log spare part usage directly from work orders to keep accurate records of parts consumed during maintenance. This helps with cost tracking, demand forecasting, and internal reporting - especially on high-turnover items like belts, bearings, or filters.

Full Inventory Audit Trail

Maintain oversight of every part movement - from work order use and stocktakes to manual adjustments and inter-warehouse transfers. Improve accountability and reduce waste or misplacement in busy maintenance environments.

Smart Cycle Counting

Keep frequently used or critical parts in check with AI-assisted cycle counts that prioritize items based on usage frequency. No more full stocktakes - just consistent, easy checks to maintain inventory accuracy.

Advanced Inventory Management

Activate Maintainly’s Inventory module to unlock features like order tracking, low stock monitoring, backorders, and multi-warehouse management - ideal for manufacturers with central stores and satellite maintenance rooms.

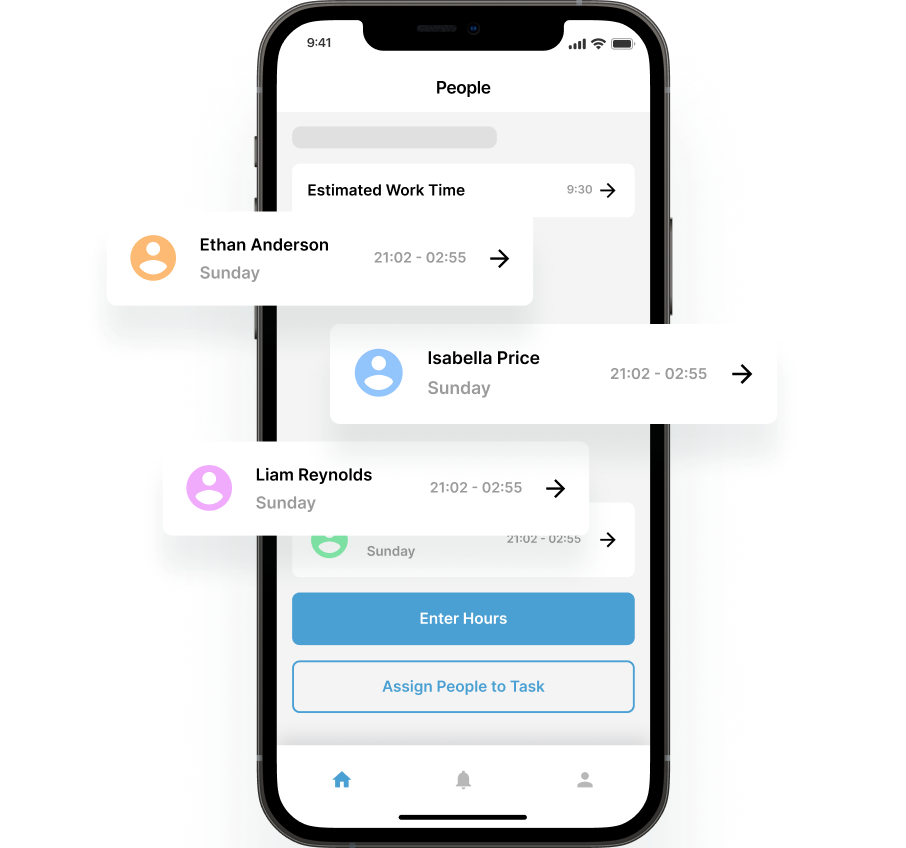

Maintain full visibility into your workforce with tools designed to help you manage technician access, capture time data accurately, and ensure your crew is qualified for the job.

Role-Based User Access

Create user accounts for different roles - from floor technicians to site admins. Limit views to only the data and features each role needs, and optionally provide asset owners visibility over their specific equipment.

Integrated Timesheets

Automatically capture technician time from completed work orders. Daily timesheets are pre-filled with job data - cutting down on admin work and improving payroll accuracy.

Advanced Timesheet Tools

Enable the Timesheet module to track overtime, shift allowances, and other payroll-related details. Export reports or connect your system via the Maintainly REST API for seamless payroll integration.

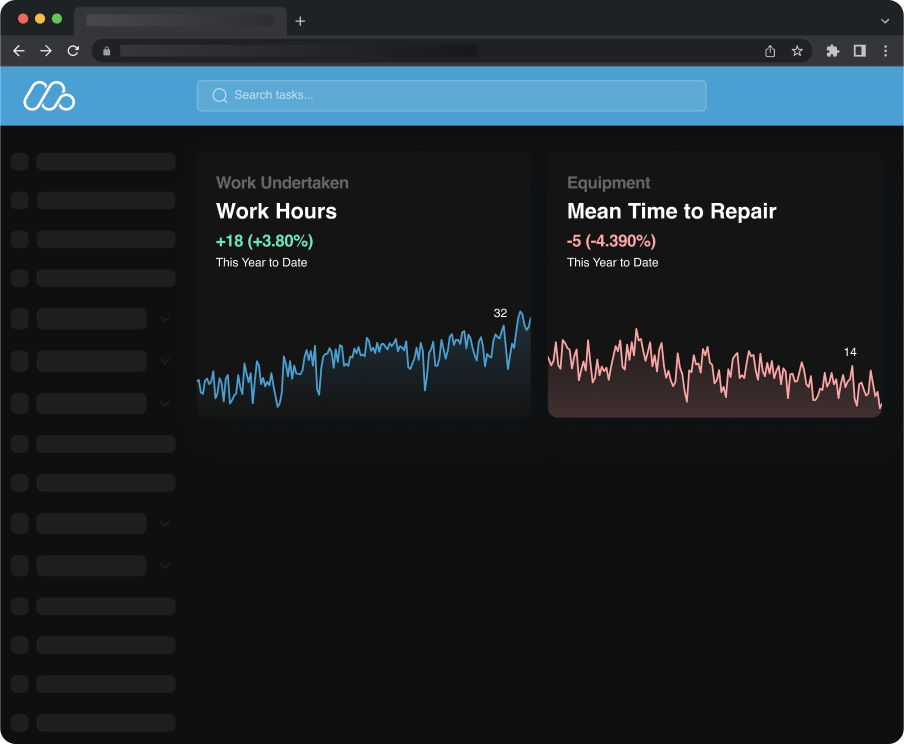

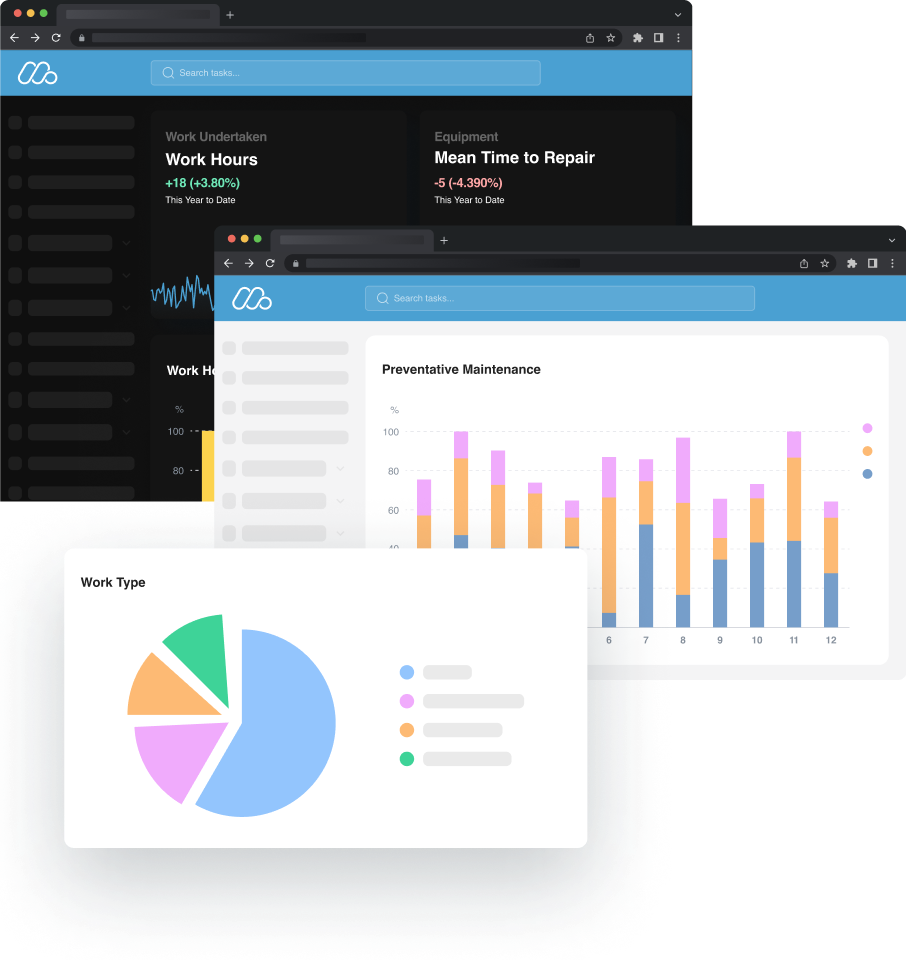

Go beyond basic audit trails. Maintainly gives your maintenance and operations teams the visibility they need to reduce downtime, diagnose recurring failures, and plan smarter maintenance strategies.

Advanced Filtering & Search

Drill deep into your work order history using AI-assisted filters. Segment by asset, technician, failure type, downtime duration, or any other field - perfect for shift supervisors, planners, or compliance managers.

Manufacturing-Focused Maintenance Reports

Gain clarity on what's happening in your plant. Access detailed reports on equipment performance, unplanned downtime, parts consumption, MTBF (Mean Time Between Failures), root cause patterns, and technician productivity.

ERP & Analytics Integrations

Easily connect Maintainly with your ERP or BI tools using our powerful REST API. Sync data with systems like SAP, Microsoft Dynamics, Power BI, and more - so your business decisions are always backed by real-time maintenance insights.

Maintenance simplified. Production amplified.

Get started in minutes, not days

Manufacturing teams can't afford software that takes weeks to implement. With preventive maintenance scheduling for one critical machine, you're already working to reduce equipment downtime, without a lengthy implementation slowing you down.

Built for manufacturing teams of any size

Built to support everything from single-operator shops to massive production facilities. Any manufacturing environment. Any manufacturing sector. Any facility size. Any number of production assets, assembly lines, or maintenance schedules. Scales with your manufacturing growth, not before.

Lowest total cost of ownership

Fast deployment keeps your production lines running, a user-friendly interface minimizes costly training downtime, included support eliminates service fees, and lean feature sets mean no paying for unnecessary enterprise bloat. Perfect for manufacturing budgets focused on ROI, not software overhead.

Dynamic, not a dinosaur

Traditional manufacturing CMMS software platforms are dinosaurs - expensive, bloated with unused features, disruptive to implement across production lines, and require costly training programs. Maintainly's CMMS for manufacturing software cuts through the complexity to deliver what manufacturing teams actually need - making it the fastest path to ROI in industrial maintenance management.

One size CMMS

doesn’t always fit all

Not yet ready for enterprise CMMS?

Mix ‘n’ match Maintainly plans and add-ons to suit. Scale only when you need to.

INVENTORY ADD-ON

- Spare part inventory management

- Inventory barcoding

- Cycle counts

- Purchase orders & stock transfers

- Stock shipments and backorders

TIMESHEETS ADD-ON

- Auto-populate timesheets with work order data

- Capture non-work-order hours in timesheets

- Overtime, banked hours & allowances

- Timesheet approvals

Savvy CMMS

customers

Maintainly.