Mobile menu

Cut the clutter: Work orders, simplified.

Create, assign, and track work orders with beautifully simple CMMS software.

Keep your team aligned and your assets running!

Work order tools

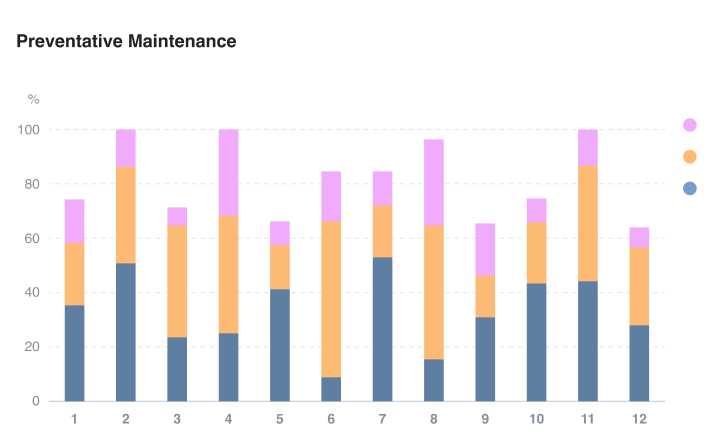

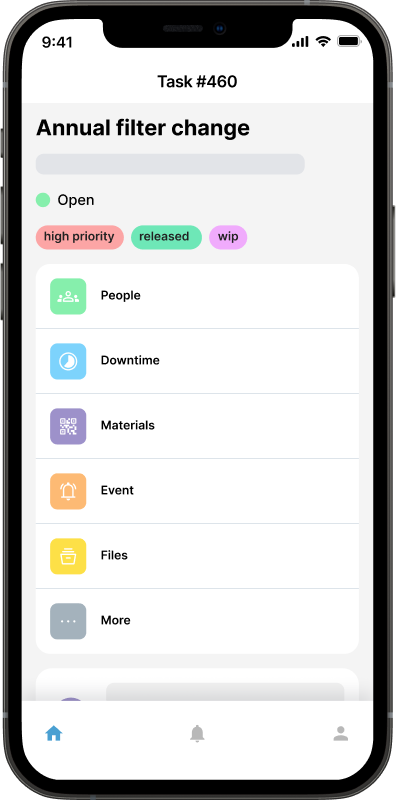

Service reports for preventive and reactive maintenance work orders help track essential data, including photos, meter readings, file uploads, and downtime. Capture key maintenance metrics to improve asset management, streamline workflows, and enhance operational efficiency with a comprehensive CMMS solution.

- Scan asset QR codes to create or view work orders

- Reactive or automated preventive maintenance tasks

- Accept, track & manage maintenance requests

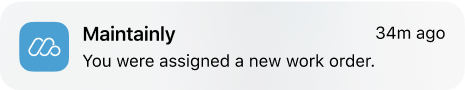

- Assign & notify users with mobile push notifications

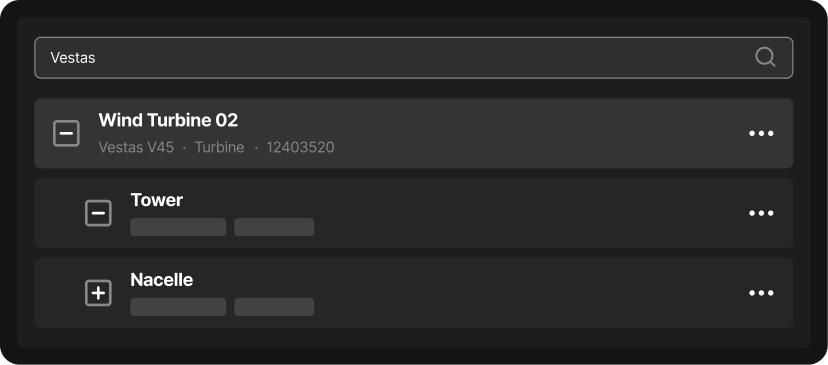

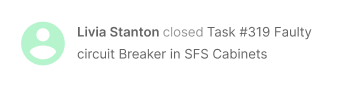

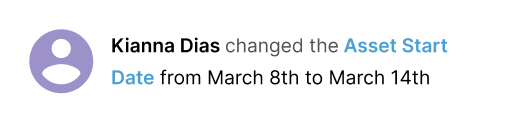

Asset management & maintenance audit trails

Easily set up asset hierarchies of any complexity with a powerful CMMS solution, tailored for industries like manufacturing, energy, hospitality, and healthcare. From hotels and aged care facilities to churches and sports complexes, Maintainly CMMS system ensures seamless asset organization and efficient maintenance management.

- Flexible hierarchy of assets with mobile-app scannable QR labels

- Detailed audit trail of maintenance history and equipment changes

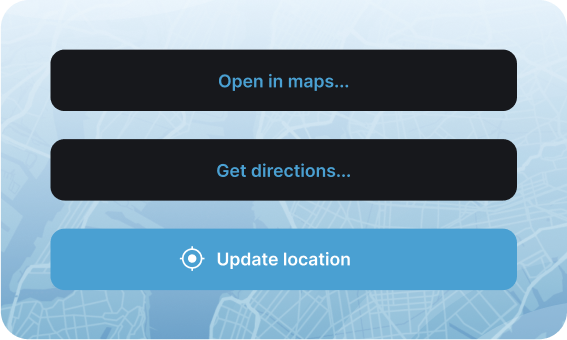

- Geolocation tracking of movable assets

- Powerful advanced filters suit different user roles & purposes

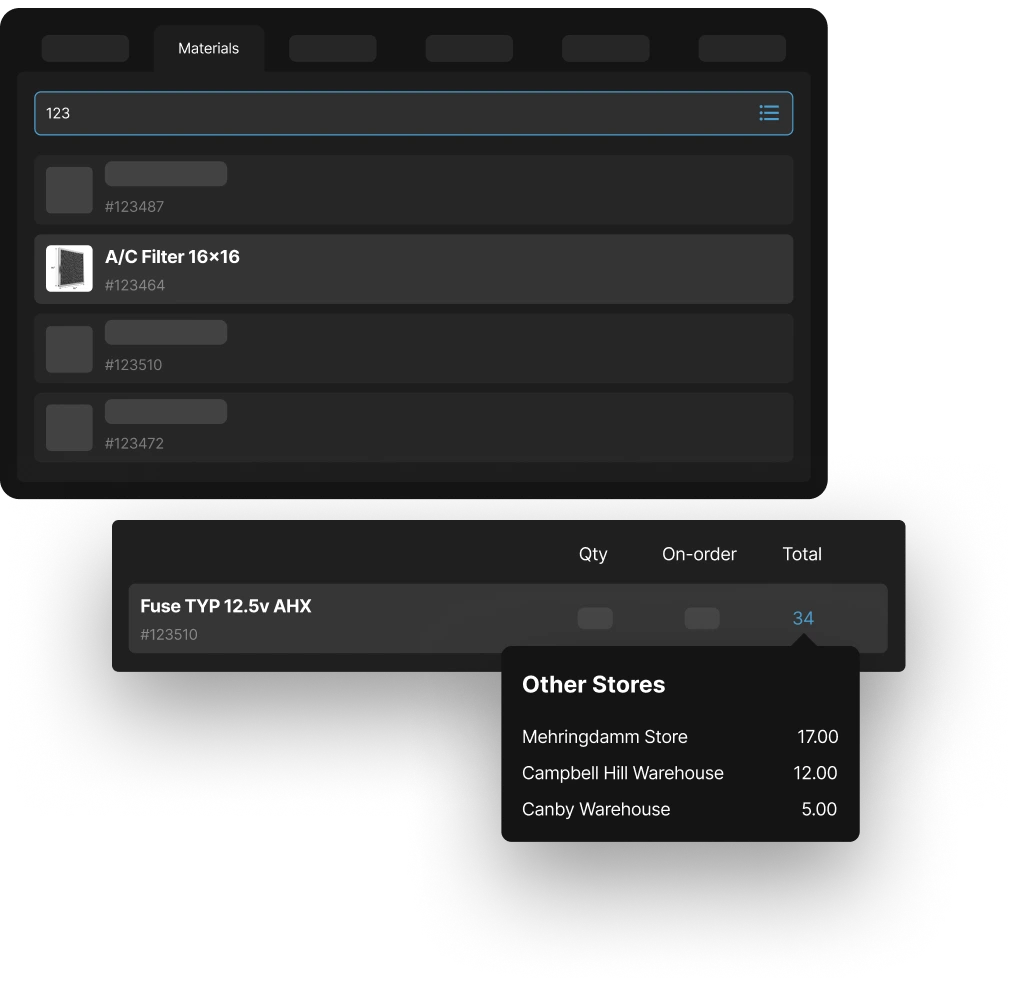

Inventory management

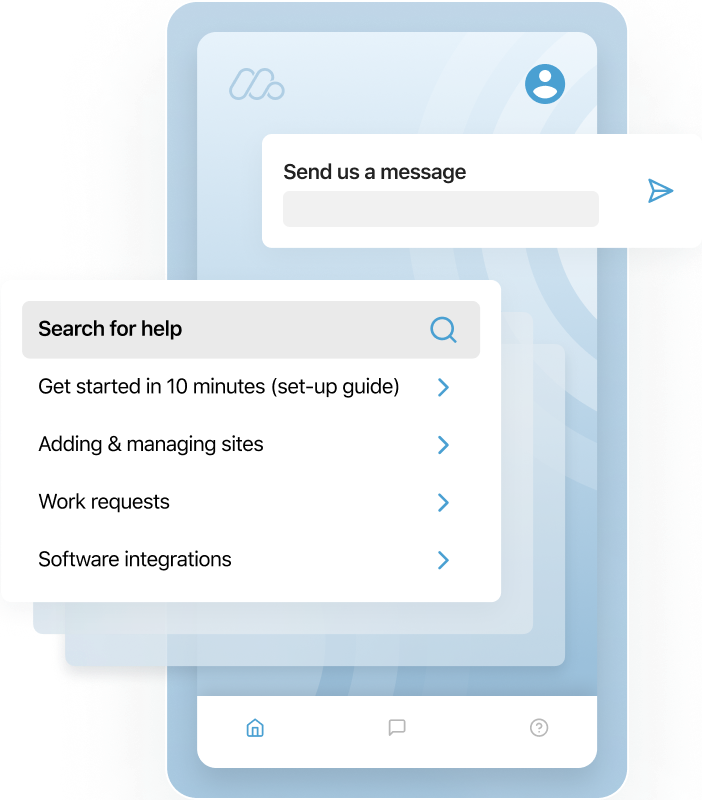

Implementing, training, and managing outdated CMMS software can be a nightmare for maintenance teams. That’s why we created Maintainly—an agile, modular maintenance management platform designed to streamline work orders, asset tracking, and preventive maintenance for teams of any size. With intuitive maintenance software features, Maintainly simplifies maintenance operations across industries like manufacturing, healthcare, hospitality, and facility management.

- Implementations that take minutes, not days or months

- Included support and set-up assistance

- It's intuitive - just 2% of customers request training from us

- It's modular - scale features only when you need them

Work order

features you'll love

Centralize your maintenance execution with a flexible work order lifecycle that eliminates paperwork and confusion. By digitizing your workflow, you ensure that every repair and inspection is documented, prioritized, and tracked from the initial request to final sign-off. This transparency allows your team to respond faster to urgent issues while maintaining a clear view of your long-term maintenance goals.

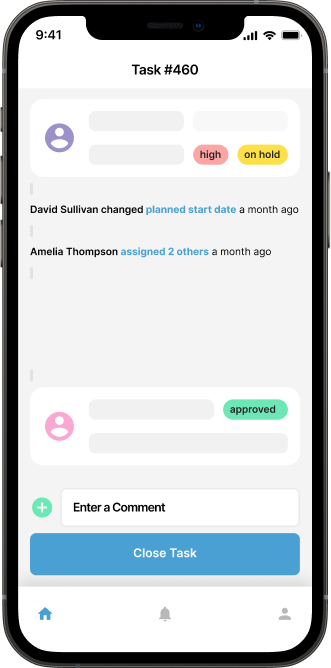

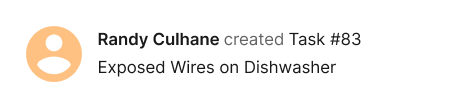

Dynamic Work Order Creation

Easily generate reactive work orders or convert service requests into actionable tasks with prioritized urgency levels.

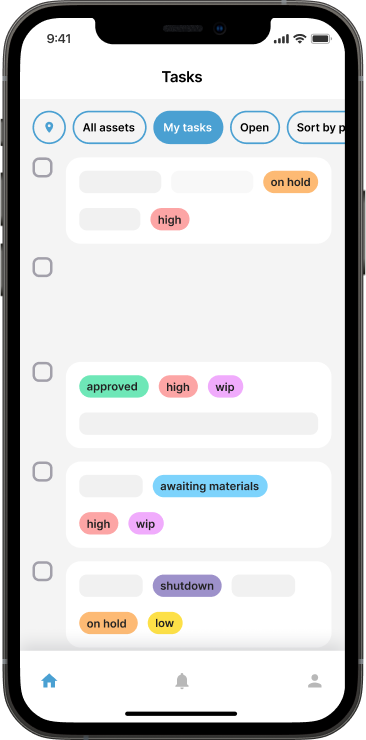

Status & Workflow Tracking

Assign custom labels, due dates and planned start dates to work orders to keep your entire team informed and aligned.

Digital Checklists & SOPs

Attach mandatory step-by-step procedures to work orders to ensure technicians follow safety protocols and quality standards.

Prioritized Backlog Management

Use powerful list views and custom filters to manage your maintenance backlog, ensuring the highest priority work is always front-and-center for your team.

Connect every work order to your equipment for a 360-degree view of your asset health and reliability. Linking tasks directly to assets builds a permanent, searchable history that is vital for making informed decisions about repairs versus replacements. With all technical data at their fingertips, your technicians spend less time searching for information and more time performing high-quality maintenance.

Work-to-Asset History

Every work order is automatically logged against the specific asset, creating a permanent audit trail of repairs and inspections.

QR Code Work Access

Technicians scan an asset’s QR label to instantly open its current work order, view past failures, or access technical manuals.

Meter-Driven Triggers

Update meter readings (hours, cycles, or miles) within a work order to automatically trigger the next scheduled service.

Downtime Documentation

Track exactly how long an asset was offline during a work order to accurately measure equipment availability and MTTR.

Manage the spare parts and materials consumed during maintenance tasks to maintain lean and accurate stock levels. By tracking parts directly within the work order, you gain total visibility into material costs and prevent stockouts that delay critical repairs. This integration ensures that your inventory data reflects the reality of the shop floor in real-time.

Parts Consumption Tracking

Search and check out parts directly within a work order to record exactly what was used and calculate total material costs.

Real-time Stock Updates

As work orders are completed, inventory levels are automatically adjusted, preventing ghost stock and unexpected shortages.

Kitting for Work Orders

Pre-allocate part kits to specific work order templates so technicians have everything they need before they head to the job.

Service & Document Attachment

Attach external service reports, vendor invoices (as files), or specialized certificates directly to the work order for centralized record-keeping.

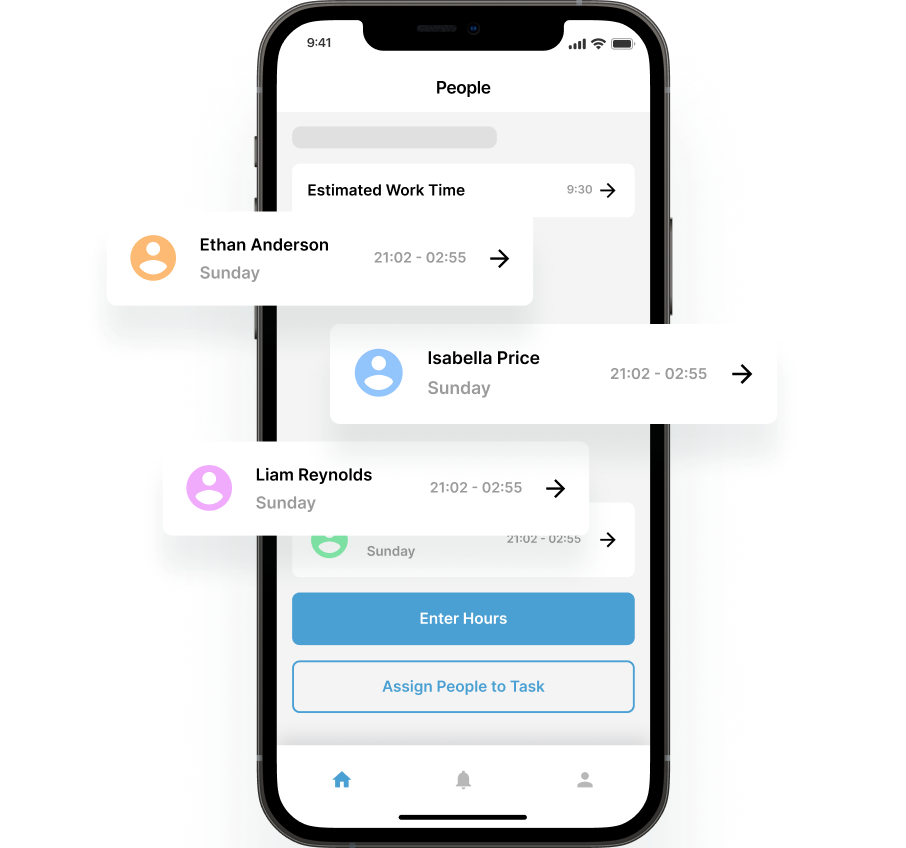

Coordinate your internal team and external contractors efficiently to ensure the right skills are applied to the right tasks. Detailed labor tracking allows you to see exactly where time is being spent, helping to identify training needs or staffing gaps. By centralizing communication, you keep your entire workforce connected, informed, and accountable for their assigned work orders.

Integrated Labor Tracking:

Technicians record their time directly within each work order, ensuring that every minute of labor is captured and automatically linked to the correct asset and task.

Work Order to Timesheet Flow

Time entries from work orders automatically populate the Timesheet module, making it easy to review daily activity, manage overtime, and track allowances without double data entry.

Flexible User Permissions

Manage access for everyone from Admins and Technicians to "Owner" levels, ensuring users only see the work orders and assets relevant to their specific roles.

Capture Non-Work-Order Time

Use the Timesheet module to record essential labor that falls outside of a specific task, such as travel time, training, or general shop maintenance, for a complete picture of your team's day.

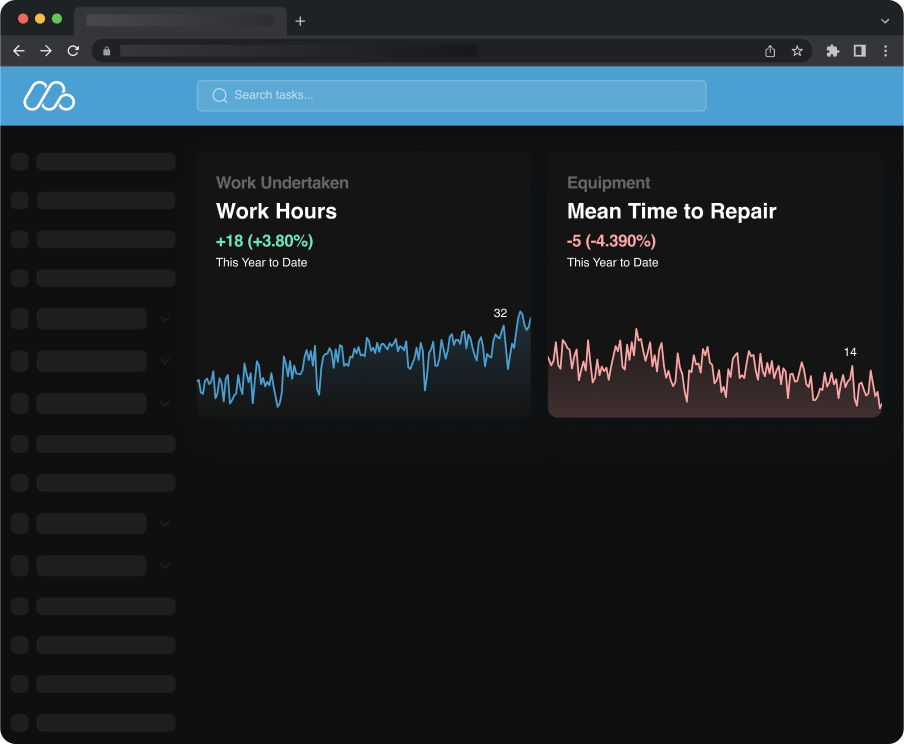

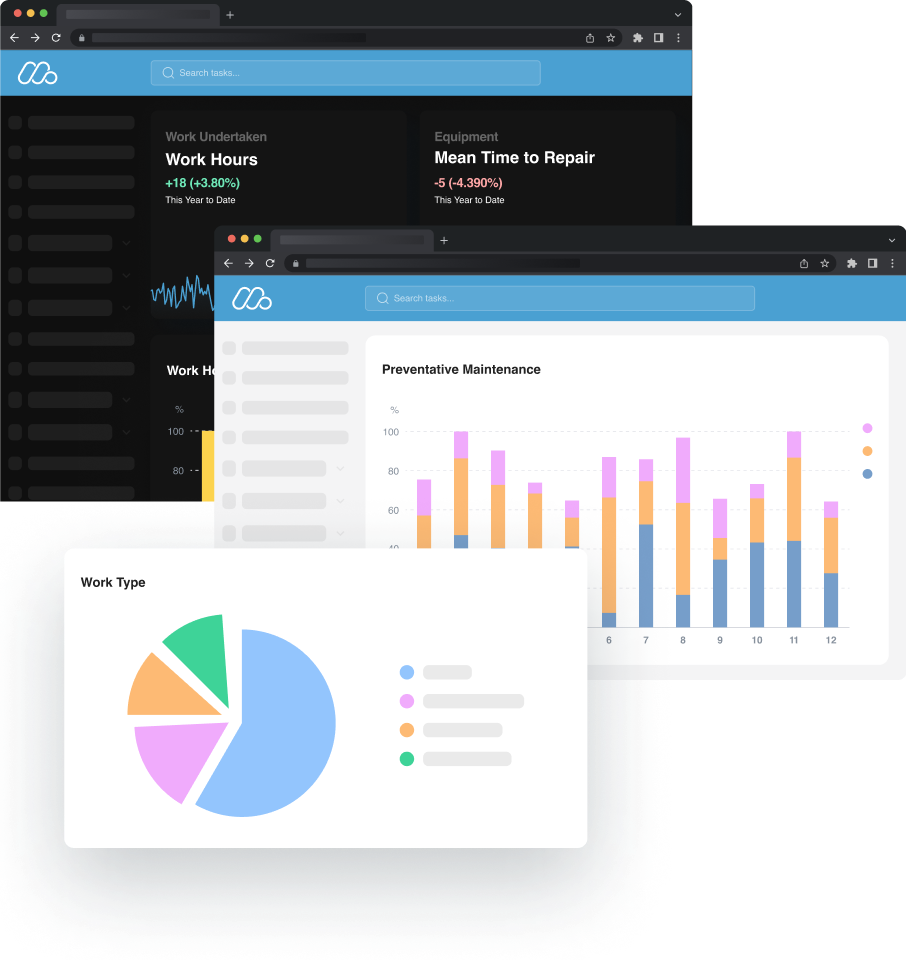

The asset audit trail for maintenance activity is just the beginning. From tracking downtime to asset alarm code occurrences and root cause analysis; the data that you need to troubleshoot asset maintenance issues, and plan and execute CMMS work orders, is right at your fingertips.

Advanced Filtering

AI-powered CMMS, data-driven advanced filtering to generate a custom report of work order data that suits different user roles, permissions & purposes.

Included Reports

A ton of standard reports covering most requirements, from work performed to asset performance analysis, downtime, mean time between failures, root cause analysis, inventory and technician performance.

API Integrations

The world is your oyster! Use the Maintainly CMMS API to create integrations with the software of your choosing, whether it's your company's ERP, BI or data analytics tool.

Way easier than traditional

work orders

Get started in minutes, not days

Transitioning from paper or spreadsheets shouldn't be a project in itself. With Maintainly, you can create your first work order and assign it to a technician in less time than it takes to find a lost clipboard. Start with one asset, one task, and see immediate clarity.

Built for maintenance teams of 1 to 1,000+

Whether you are a solo operator managing a handful of work orders or a national enterprise handling thousands of monthly requests, Maintainly scales with you. Maintainly handles the volume without the complexity, ensuring your workflow remains snappy no matter how large your team grows.

Lowest total cost of ownership

Eliminate the hidden costs of "traditional" work order management, like lost productivity from missing info or the manual labor of data entry. With a lightning-fast setup and an interface so intuitive it requires little to no formal training, you get a professional-grade system at a fraction of the usual cost.

Dynamic, not a dinosaur

Traditional work order systems are often rigid and frustratingly slow. Maintainly is built for the modern workforce: mobile-first, cloud-based, and designed to move as fast as your technicians do. It’s the fastest way to get through a to-do list, without the administrative headache.

Mix ‘n’ match Maintainly

plans to fit

Not yet ready for enterprise-grade maintenance management?

Mix ‘n’ match Maintainly plans and add-ons to suit your business. Scale only when you need to.

INVENTORY ADD-ON

- Spare part inventory management

- Inventory barcoding

- Cycle counts

- Purchase orders & stock transfers

- Stock shipments and backorders

TIMESHEETS ADD-ON

- Auto-populate timesheets with work order data

- Capture non-work-order hours in timesheets

- Overtime, banked hours & allowances

- Timesheet approvals

Savvy CMMS

customers

Maintainly.