Why It's Time to Ditch Spreadsheets for CMMS in Maintenance Management

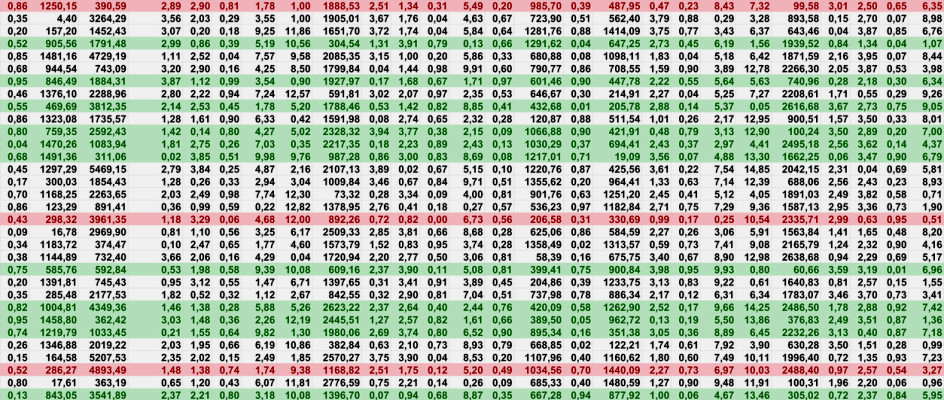

Efficient maintenance management is crucial to uptime, cost control, and operational excellence. And yet, many maintenance teams still rely on spreadsheets to track tasks, manage assets, and schedule preventive maintenance. While spreadsheets may seem convenient at first, they quickly become a bottleneck as operations grow more complex.

It's time to leave the spreadsheets behind and move into the future with a Computerized Maintenance Management System (CMMS).

The Problem with Spreadsheets in Maintenance

Spreadsheets are powerful tools for organizing data, but they were never designed to manage dynamic, collaborative workflows. Here’s where they fall short:

1. Prone to Human Error

Manual data entry, forgotten updates, and incorrect formulas are common issues with spreadsheet-based systems. A single typo can throw off an entire maintenance schedule or obscure a critical failure.

2. Lack of Real-Time Visibility

Spreadsheets provide static snapshots. They don’t offer real-time updates on work order statuses, technician workloads, or asset conditions. You can’t manage what you can’t see.

3. Poor Collaboration

Maintenance requires coordination across teams and departments. But emailing spreadsheets back and forth or sharing static links often leads to version control nightmares, confusion, and duplicated efforts.

4. Limited Scalability

As your operations grow, so does the complexity of your asset hierarchy, maintenance tasks, and reporting needs. Spreadsheets quickly become unmanageable, error-prone, and out of sync.

5. No Automation

Spreadsheets can’t trigger preventive maintenance based on runtime data or meter readings. Nor can they send alerts, assign tasks, or integrate with IoT devices or other software systems.

The Case for CMMS

A CMMS (Computerized Maintenance Management System) is designed to address all the shortcomings of spreadsheet-based maintenance tracking. Let’s explore the benefits:

Real-Time Work Order Management

A CMMS enables maintenance managers to instantly create, assign, and monitor work orders as soon as an issue is reported. This instant visibility ensures high-priority issues are dealt with quickly, and no tasks fall through the cracks. Work orders can be updated on the go, reducing paperwork and enabling a faster response.

Automated Preventive Maintenance

Rather than relying on static calendars or memory, a CMMS allows you to schedule maintenance based on time intervals, usage metrics, or sensor data. Automatic triggers can initiate tasks and send reminders to technicians before breakdowns occur. This minimizes unplanned downtime and extends asset life.

Centralized Asset Database

Every piece of equipment has a home in your CMMS, complete with specifications, maintenance history, warranties, and documentation. This eliminates the need to sift through file cabinets or old emails, making it easy for technicians to find the information they need, right when they need it.

Seamless Collaboration

With a CMMS, maintenance becomes a truly team-based effort. Technicians, supervisors, and even third-party vendors can access tasks from any device, log updates, and communicate in real time. Everyone stays on the same page, eliminating confusion and delays caused by scattered information.

Actionable Reporting and Insights

CMMS software collects and analyzes maintenance data automatically, turning it into dashboards and reports. You can identify trends in asset performance, evaluate technician efficiency, and plan smarter. This data-driven approach supports continuous improvement and long-term strategic planning.

Key Features That Make the Switch Worthwhile

CMMS Feature | Replaces Spreadsheet Pain Point |

|---|---|

Real-Time Dashboards | Static data snapshots |

Mobile Work Order Access | Manual printouts and updates |

Automated Scheduling | Calendar reminders and manual checks |

Inventory Tracking | Disconnected stock lists and emails |

Role-Based Permissions | Universal access without accountability |

System Integrations | Copy-pasting data between disconnected apps |

Real-World Results

After switching from spreadsheets to a CMMS, a mid-sized US-based manufacturing firm specializing in precision metal parts experienced transformative results within just six months of using Maintainly:

40% reduction in unplanned downtime: With automated preventive maintenance scheduling, the team started catching equipment issues before they turned into costly breakdowns.

15% improvement in technician productivity: Technicians access work orders on their mobile devices, and started moving from job to job, rather than returning to the site office constantly.

10+ hours saved per week on manual reporting: Maintenance managers no longer have to compile reports manually at the end of each day. Before and after photos are taken on technician's phones.

These improvements helped move from a reactive, spreadsheet-bound workflow to a proactive maintenance culture. CMMS didn’t just improve efficiency - it delivered measurable business impact.

How to Make the Switch

Transitioning from spreadsheets to a CMMS doesn’t have to be painful. Here are a few steps to make the process smoother:

Audit your current process: Identify what’s working and what’s causing delays or errors.

Define your must-have features: Make a list of what you need - preventive scheduling, mobile access, reporting, etc.

Choose a CMMS that fits your team: Look for user-friendly platforms that require minimal training and can scale with your business.

Import your data: Most CMMS tools offer spreadsheet import tools to make onboarding fast.

Train your team: Ensure everyone understands how to use the system and why it matters.

Spreadsheets may have been a good starting point, but they can’t keep up with the demands of modern maintenance operations. With a CMMS, you gain visibility, automation, and control - all essential to running a smooth, efficient, and scalable maintenance program.

The time to switch is now. Let your maintenance team do what they do best, with the right tools to back them up.

Explore Maintainly’s CMMS and start your free trial today.