Setting up an Asset Hierarchy - a Guide to Selecting Which Equipment to Include

What is an Asset Hierarchy?

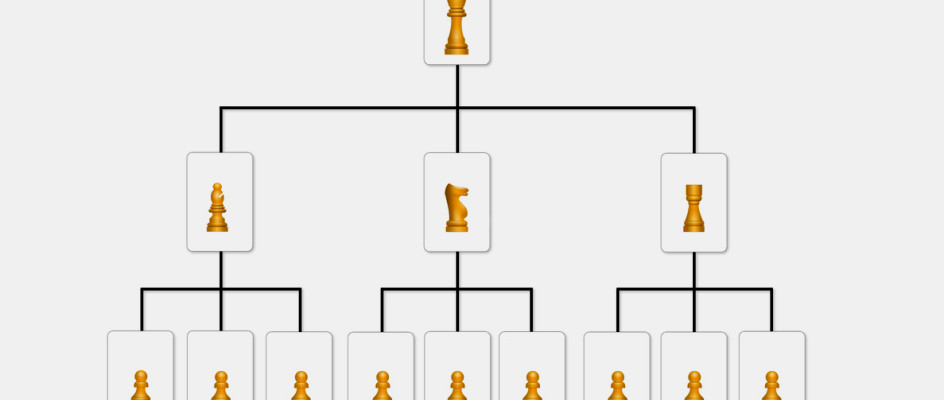

An asset hierarchy is a structured framework that organizes and categorizes assets within an organization into a logical, multi-level arrangement. This hierarchy typically follows a parent-child relationship, where assets are grouped from broad, overarching categories down to more specific, individual items. The goal of an asset hierarchy is to facilitate better management, tracking, and maintenance of assets by providing a clear, organized structure.

Each higher-level category (parent) encompasses multiple lower-level items (children). This relationship helps in drilling down from a broad category to individual assets for detailed management and analysis.

In a Computerized Maintenance Management System (CMMS), the asset hierarchy is crucial for organizing and managing maintenance tasks.

Which Equipment to Include?

Determining which assets and equipment should be tracked via work orders to maintain a full asset history of previous maintenance work involves considering several factors. The exact make-up and format of an asset hierarchy will depend on many factors, such as the type of assets being tracked, their complexity in terms of sub-assets (child assets), the industry, as well as your company's maintenance management and reporting goals.

Here are ten factors to consider when setting up an asset hierarchy:

Asset Criticality

Begin by assessing the criticality of each asset or equipment. Identify assets that are crucial for the smooth functioning of your operations, such as equipment directly impacting production, safety, or regulatory compliance. These assets are typically high-priority candidates for work order tracking.

Maintenance Frequency

Consider the maintenance frequency required for each asset. Assets that require regular inspections, preventive maintenance, or servicing should be tracked via work orders to ensure that maintenance tasks are scheduled and completed on time.

Cost and Complexity

Evaluate the cost and complexity associated with maintaining each asset. Expensive or intricate equipment usually requires detailed maintenance records to track repairs, part replacements, and other activities that impact the asset's reliability and performance.

Safety and Compliance

Identify assets with safety or compliance implications. Equipment that poses risks to employees, the environment, or regulatory compliance should be tracked through work orders. This ensures that all necessary inspections, tests, and certifications are documented, maintaining a comprehensive asset history.

Equipment History

Examine the historical maintenance records of each asset. Assets that have had significant breakdowns or recurring issues in the past should be considered for work order tracking. This allows for better analysis of patterns, identification of root causes, and implementation of appropriate corrective measures. This may also change over time, so you can always add to your asset hierarchy as needs change.

Reliability and Downtime Impact

Assess the impact of asset failures or downtime on your operations. Assets that, if malfunctioning, significantly disrupt productivity, cause delays, or result in revenue loss should be tracked via work orders. This helps in monitoring maintenance activities, tracking performance metrics, and reducing unplanned downtime.

Equipment Age and Lifecycle

Consider the age and stage in the lifecycle of each asset. Older assets or those nearing the end of their lifecycle often require increased attention and documentation to manage their maintenance and replacement strategies effectively.

Manufacturer Recommendations

Consult the manufacturer guidelines and recommendations for equipment maintenance. Some manufacturers provide specific instructions or schedules for maintenance activities. Following these recommendations and tracking the associated work orders can help maintain warranty compliance and equipment performance.

Organisational Requirements

Take into account any specific organisational requirements or industry standards that mandate asset tracking. Certain industries, such as healthcare, aviation, or manufacturing, may have regulatory or quality assurance standards that necessitate comprehensive work order tracking for specific assets. Other industries like healthcare (eg. gyms), churches and hospitality do not require intricate detail.

Serial Numbers

The existence of a serial number is usually a good indicator that the equipment should be included in your asset hierarchy. If it's likely that these assets will be replaced at some point then that also adds weight to them being added to the hierarchy.

Regularly review and reassess your asset tracking approach. As business needs change or new equipment is introduced, it is important to reevaluate which assets should be tracked via work orders to maintain an up-to-date asset history.

By considering these factors, you can determine which assets and equipment should be tracked via work orders, enabling you to maintain a comprehensive asset history of previous maintenance work. This information facilitates informed decision-making, improves asset performance, and helps ensure the efficient and effective operation of your organisation.

Try Maintainly CMMS free for 14 days, or learn what is & is not a traceable assets.

Further Reading

What is CMMS?

A Computerized Maintenance Management System (CMMS) is a software solution that streamlines and automates maintenance management processes, including work orders, preventive maintenance, asset tracking, and inventory management, to optimize the efficiency and performance of organizational assets. But let's dig into the details...

Read more →