Cycle Counts Save you Money

A cycle count feature of a CMMS can save your business significant money by improving inventory accuracy, reducing operational disruptions, and allowing efficient resource allocation. Here’s an in-depth exploration of the benefits and key elements of cycle counting and how this method enables businesses to optimize inventory management, improve resource use, and ultimately drive savings.

Unmatched Accuracy in Inventory Management

Cycle counts involve counting subsets of inventory on a rolling basis rather than conducting a complete physical inventory at once. This continuous approach offers several benefits:

Inventory Accuracy on a Rolling Basis: Unlike annual or biannual counts, cycle counting ensures that inventory is regularly updated, which keeps stock levels accurate throughout the year. Regular cycle counts help in identifying discrepancies early, minimizing the chances of stockouts, overstocking, or deadstock, each of which has cost implications.

Reduced Errors with Smaller Counts: Cycle counts are often more accurate because employees are counting smaller portions of inventory at a time, which reduces counting fatigue and improves focus. Smaller, regular counts allow for a meticulous approach, catching inaccuracies promptly, and leading to fewer mistakes overall.

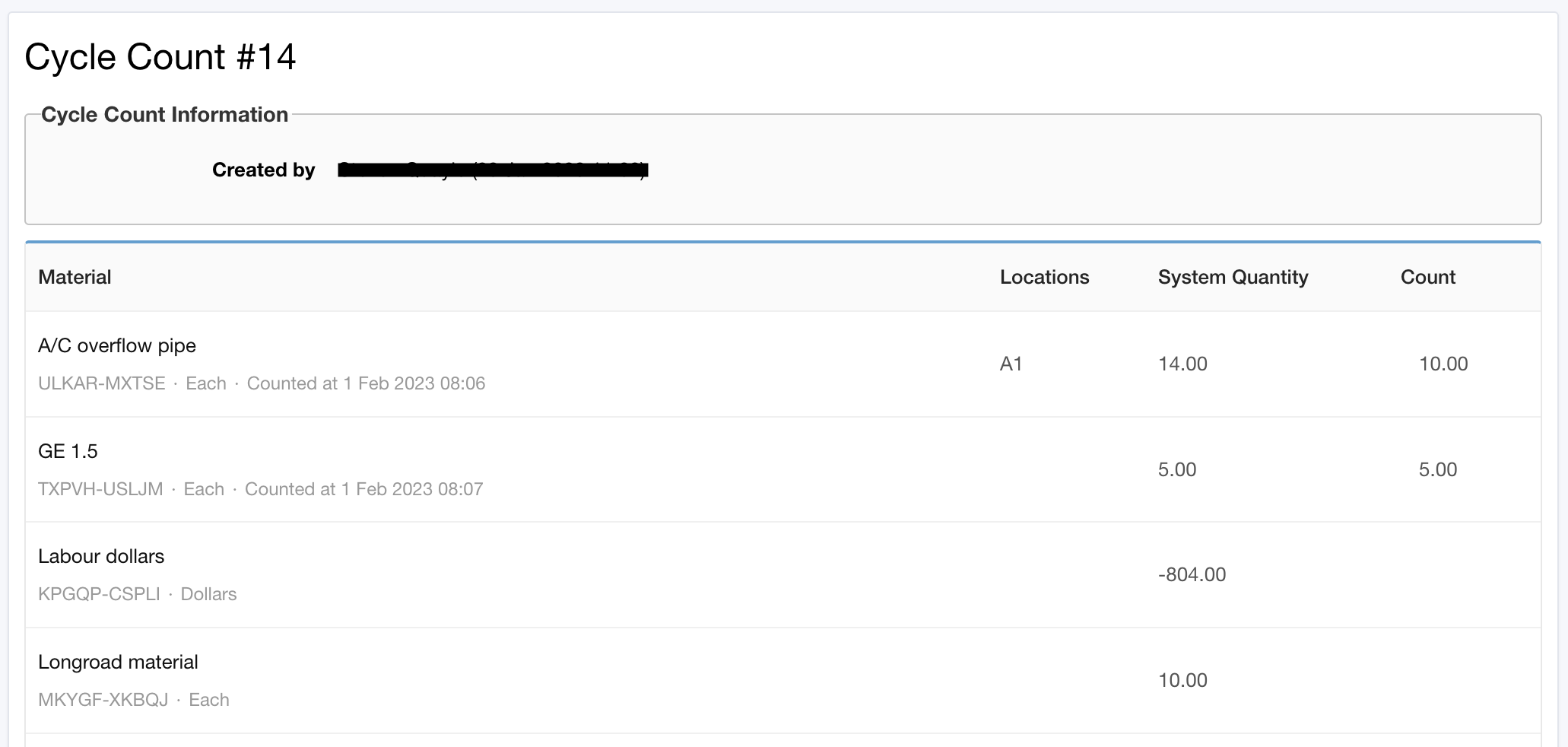

Prioritization of Frequently Moved Inventory: Many cycle count systems employ an ABC approach, which prioritizes high-value or high-movement items (Category A) for more frequent counts. This targeted counting means that inventory items most important to business continuity are always accurate, which directly impacts profitability. In Maintainly CMMS, we such an approach to cycle counts, but also introduce a second and third category in our proprietary cycle count algorithm.

By improving the accuracy of high-velocity items and continuously updating stock levels, cycle counts contribute to better purchasing decisions and reduced emergency restocking, all of which translate to cost savings.

Cost & Resource Savings Through Operational Continuity

Cycle counting has a distinct advantage over full physical inventories in that it doesn’t require stopping business operations. This continuity is critical for businesses that cannot afford extended shutdowns. Here’s how cycle counting helps in resource optimization and cost savings:

No Operational Halt: Conducting full inventory requires halting operations, usually leading to lost productivity and potential revenue delays. Cycle counting avoids this by allowing employees to conduct small, manageable counts without impacting other functions.

Reduced Labor Costs: Traditional physical counts are labor-intensive and often require additional, temporary staff or overtime hours. Cycle counting, by contrast, integrates inventory management into the regular workflow, reducing the need for additional labor and overtime, which can be costly.

Savings in Errors and Adjustments: Cycle counts tend to reduce the frequency of inventory discrepancies, which means businesses can avoid the administrative and logistical costs associated with resolving errors. With accurate inventory levels, the business reduces the cost of errors in reordering, shipping, and even accounting, all of which contribute to operational efficiency and cost reduction.

Improved Customer Service & Satisfaction

Improved Customer Service & Satisfaction

Accurate inventory data positively impacts customer satisfaction and sales:

Fewer Stockouts and Overstocks: By keeping more accurate, timely records of inventory, businesses can reduce stockouts, which lead to lost sales, and overstocks, which tie up capital in unsellable goods. Customer satisfaction and trust in the business improve as products are more consistently available and accurately listed online or in-store.

Enhanced Order Fulfillment Accuracy: When inventory is regularly counted and discrepancies corrected immediately, it’s much easier to deliver accurate order fulfilment, which is essential for customer satisfaction. Customers appreciate reliability, and a strong cycle count program makes it possible to promise and meet delivery deadlines more accurately.

Financial Savings & Improved Cash Flow

Cycle counts contribute directly to better financial outcomes in several ways:

Reduced Inventory Carrying Costs: With more accurate inventory data, companies can optimize stock levels, reducing the amount of cash tied up in inventory. This reduction directly lowers carrying costs and enables a more agile response to demand changes.

Fewer Write-Offs and Adjustments: Traditional physical inventory counts often result in significant write-offs, where companies must account for missing or damaged goods in bulk. Cycle counts ensure that inventory levels are accurate on an ongoing basis, allowing companies to adjust smaller discrepancies over time rather than dealing with large discrepancies in a single count.

Improved Demand Forecasting: Accurate cycle count data enables more precise demand forecasting and inventory planning, reducing the risk of costly overproduction or underproduction. As a result, businesses can better allocate their resources, aligning inventory purchases with true demand.

Long-Term Operational Efficiency

Cycle counting fosters a culture of continuous improvement and accountability within the organization. By frequently checking and adjusting inventory levels, employees become more attuned to the intricacies of inventory management and develop stronger accountability for stock accuracy. This contributes to long-term operational efficiency and can lead to the adoption of best practices in inventory handling and storage, which help reduce breakage, theft, or misplacement.

Implementing an Effective Cycle Count Program

To gain these benefits, businesses should carefully plan and implement a cycle counting program:

Choose an Appropriate Counting Method: There are different methods for cycle counting, including ABC counting, process control group counting, and location-based counting. Selecting the right method based on business needs and inventory characteristics is essential for maximizing cycle counting effectiveness.

Leverage Technology for Accuracy: Many businesses now use inventory management software and barcode scanning technology to conduct cycle counts. These tools increase counting speed and accuracy, reduce errors, and ensure that inventory data integrates seamlessly with other business systems.

Establish Clear Policies and Schedules: Consistency is key to effective cycle counting. Establishing clear policies for which items to count, how often, and what method to use allows for a smoother implementation and ensures accurate, actionable data.

Train Employees in Inventory Best Practices: Employee training is essential for successful cycle counting. Proper training in counting techniques and inventory handling can significantly improve accuracy, reduce counting times, and enhance employee engagement with the process.

Cycle Counts as a Smart Business Strategy

In summary, Maintainly cycle counting offers unmatched accuracy in inventory management, reduces operational disruptions, and improves resource use, leading to significant cost savings for businesses. It empowers businesses to manage inventory on a rolling basis, making it easier to detect and resolve discrepancies promptly. By fostering a proactive approach to inventory accuracy, cycle counting contributes to better financial outcomes, improved customer satisfaction, and long-term operational efficiency.

Embracing cycle counting as part of a comprehensive inventory management strategy enables businesses to remain agile, competitive, and cost-effective.

Further Reading

What is CMMS?

A Computerized Maintenance Management System (CMMS) is a software solution that streamlines and automates maintenance management processes, including work orders, preventive maintenance, asset tracking, and inventory management, to optimize the efficiency and performance of organizational assets. But let's dig into the details...

Read more →

Benefits of CMMS

CMMS will aid and inform technicians out in the field, as well as decision makers, on maintenance work that has been done, will be done soon, or is planned to be done in the future. Broadly speaking, the benefits of CMMS can be broken down into three categories: management; visibility; and cost control.

Read more →

What is the 75% Maintenance Rule in Asset Management: When to Repair or Replace

What exactly is the 75% maintenance rule, how is it applied, and why should it be integrated into your Computerized Maintenance Management System (CMMS)?

Read more →