Preventative Maintenance is now Task Templates + Automations

Preventative Maintenance Schedules

Previously when you created and managed preventative maintenance in Maintainly, it was done by adding schedules to individual assets, or to asset models (that were applied to each asset that was of that same model).

After establishing those schedules, the date on which preventive maintenance fell due would be determined by the individual maintenance start date on each asset. Whilst is was easy enough to monitor a single date, it made it difficult to manipulate due dates on preventative maintenance tasks, because changing the maintenance start date would impact every maintenance schedule that was applicable to that piece of equipment.

Here's how we have addressed that and upgraded the way that preventative maintenance is managed in Maintainly.

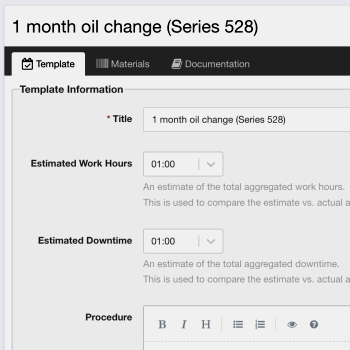

Task Templates

The components of the previous preventative maintenance schedules, other than the timing or trigger rules, have been extracted and placed into what we're calling Task Templates.

This means that the things you want to be pre-populated and appear in the preventative maintenance tasks each and every time like the work procedure to be followed, images, pdf's, work time estimates, downtime estimates and spare part material kits are added once to a task templates. Then, whenever the task template is used by an automation (see below) to trigger a preventive maintenance task, all of the data that's held in the task template will pre-populate the tasks, ready for technicians to start work.

As the preventative maintenance requirements change over time on an asset, so too can the task templates. Simply modify or update the task template with the latest procedure or required data and this will be used going forward whenever an automation triggers the preventative maintenance task.

Preventative Maintenance Automations

Previously, after establishing a maintenance schedule, you were required to re-visit one or more assets as a separate process to define the maintenance start date. Therefore, it was a disjointed process of: create asset > add a schedule to the asset > return to asset settings and set the appropriate date. Sometimes it was difficult to determine which date should be set if an asset had many preventative maintenance tasks, because they would all have to work in with each since they were using the same date to inform the trigger.

Automations makes the process of establishing preventive maintenance much, much easier:

Each preventative maintenance schedule gets it's own automation, and;

Each automation simply defines when the next due date is, and then the automation tasks over the creation of preventative maintenance tasks going forward based on the interval rules that you define.

Automatons can be thrown away

If the desired due date changes over time then an automation can simply be discarded and a new added. This has several advantages over constant meddling with existing schedules:

Automations are far easier to understand for your users;

it only refers to that one preventative maintenance schedule

Automations don't hold much data (most of the data is held in the task template) so it doesn't result in more workload (eg. no need to recreate an entire schedule with all of the technical data); it's simply defining the trigger rules.

There's less worry that one user is going to 'mess with' your well-designed preventative maintenance schedules;

Archiving an automation and then adding a new one won't result in conflicts;

If preventative maintenance has to stop on an asset, it can simply be discarded and a new one added (with appropriate due date timing) added whenever you're ready to recommence.

Automations can be time-based (eg. weekly, monthly, quarterly, annually, etc.) or metric-based (eg. odometer, temperature, wind speed readings, etc.);

What's changed?

Apart from the improved efficiency and simpler process described above, there are some interface changes that existing CMMS users will notice:

You will no longer see Preventative Maintenance in the left side menu. Instead:

Tasks templates will be added via Tasks > Task templates and;

Automations will be added via Assets > filter for and then click required asset > Automations tab.

Previously, after establishing a maintenance schedule, you were required to re-visit one or more assets as a separate process to define the maintenance start date.

You will no longer need to add a maintenance start date to individual assets in order to generate preventative maintenance tasks. Therefore:

The Maintenance Start Date field on assets no longer exists;

Existing maintenance start dates have been moved to be a custom field on the asset, but now perform no particular function (the data can be removed, at your option), and;

Due dates for time-based maintenance will now be determined by the individual dates set on the automations (instead of an asset maintenance start date.

Any existing Operating Hours or Production Counter data on tasks has been migrated to be a metric on the asset.

A single task template could be used over and over again with any number of assets, but each individual asset could have its own unique automation rules that define when to trigger a preventative maintenance task;

All existing preventative maintenance schedules have been migrated over to the new method for you.

So, to summarise the procedure changes for exisiting Maintainly users:

Create a task template;

Add an automation to an asset, stipulating which task template is to be used and why or when to trigger the task.

We're really existed about these changes, not only because of the super-simple, streamlined process for creating preventative maintenance schedules, but also because the future functionality opportunities that it has now opened up. We're looking forward to bringing you more initiatives in this space.

Check it out and, as always, drop us a line to let us know what you think.

Further Reading

What is CMMS?

A Computerized Maintenance Management System (CMMS) is a software solution that streamlines and automates maintenance management processes, including work orders, preventive maintenance, asset tracking, and inventory management, to optimize the efficiency and performance of organizational assets. But let's dig into the details...

Read more →

Benefits of CMMS

CMMS will aid and inform technicians out in the field, as well as decision makers, on maintenance work that has been done, will be done soon, or is planned to be done in the future. Broadly speaking, the benefits of CMMS can be broken down into three categories: management; visibility; and cost control.

Read more →

What is the 75% Maintenance Rule in Asset Management: When to Repair or Replace

What exactly is the 75% maintenance rule, how is it applied, and why should it be integrated into your Computerized Maintenance Management System (CMMS)?

Read more →