What is Maintenance Software?

Peeling Back the Layers

The spotlight is shining brightly on Computerized Maintenance Management Systems (CMMS) with record levels of adoption as businesses continue to migrate from their manual processes. This sophisticated tool suite is reshaping how businesses maintain their assets, promising safety, enhanced longevity, and maximum productivity. But stepping back for a moment, as managers, it isn’t enough to know what the value of this software is to the enterprise, and it’s vitally important to be able to explain to other stakeholders what this maintenance software magic is and how it redefines organizational maintenance strategies.

Imagine having a digital command center at your fingertips that simplifies and streamlines every aspect of maintenance management. That's maintenance software for you—a technological beacon that transforms cluttered, paper-heavy processes into a sleek, digital operation. Acting as a central hub for maintenance, it meticulously organizes asset information, schedules, inventory, and work order details. The shift to digital eliminates the chaos of manual record-keeping, leading to operations that are not just smoother but more accurate and efficient.

What's the Difference between Maintenance Software & CMMS?

Maintenance Software

Maintenance software is a broad category that includes any software designed to help manage and streamline maintenance activities. This can range from basic tools to comprehensive systems.

Key features of maintenance software:

Basic Task Management: Simple software may offer basic scheduling and task tracking capabilities.

Variety of Tools: Can include different types of software like simple spreadsheet templates, mobile apps, or more complex applications designed for specific industries or tasks.

General Focus: May not have a comprehensive set of features for maintenance management but can be adapted to various maintenance needs.

CMMS

CMMS

A CMMS is a specialized type of maintenance software specifically designed to automate and streamline maintenance management processes. It focuses on the maintenance needs of organizations, providing a centralized platform to manage all maintenance activities.

Key features of CMMS:

Work Order Management: Creation, assignment, tracking, and closure of work orders.

Preventive Maintenance: Scheduling and tracking of preventive maintenance tasks to avoid equipment failure.

Asset Management: Detailed records of equipment and assets, including maintenance history, warranties, and performance data.

Inventory Management: Tracking of spare parts and inventory levels to ensure necessary parts are available when needed.

Reporting and Analytics: Detailed reports and analytics to help in decision-making and improving maintenance processes.

Compliance Tracking: Ensures maintenance activities comply with industry regulations and standards.

Integration: Often integrates with other enterprise systems like ERP, IoT devices, and more.

Key Differences between Maintenance Software & CMMS

Scope and Specialization:

Maintenance Software can be broad and may cater to various maintenance-related tasks without being specifically designed for maintenance management, whereas CMMS is specifically designed for comprehensive maintenance management with a focus on automating and optimizing all maintenance processes.

Functionality:

Maintenance Software may offer limited or generalized functionality that can be adapted for maintenance purposes, whereas CMMS provides specialized and extensive features tailored to maintenance management, including preventive maintenance, work order management, and asset tracking.

Integration and Scalability:

Maintenance Software can lack integration capabilities with other enterprise systems and could be less scalable, whereas CMMS typically offers robust integration options and can scale to accommodate the growing needs of an organization.

Industry Usage:

Maintenance Software is used across various industries in a more general sense, whereas CMMS is specifically targeted towards industries with significant maintenance needs such as manufacturing, healthcare, facilities management, and utilities.

The CMMS Evolution

Among the many maintenance tools, CMMS stands tall, offering a robust solution that touches every corner of maintenance management. Far beyond mere scheduling, CMMS is a powerhouse equipped with features for detailed asset management, proactive work order management, inventory oversight, preventive care, and compliance monitoring. It gives maintenance chiefs the insight to optimize tasks, foresee potential hiccups, and keep the business running smoothly.

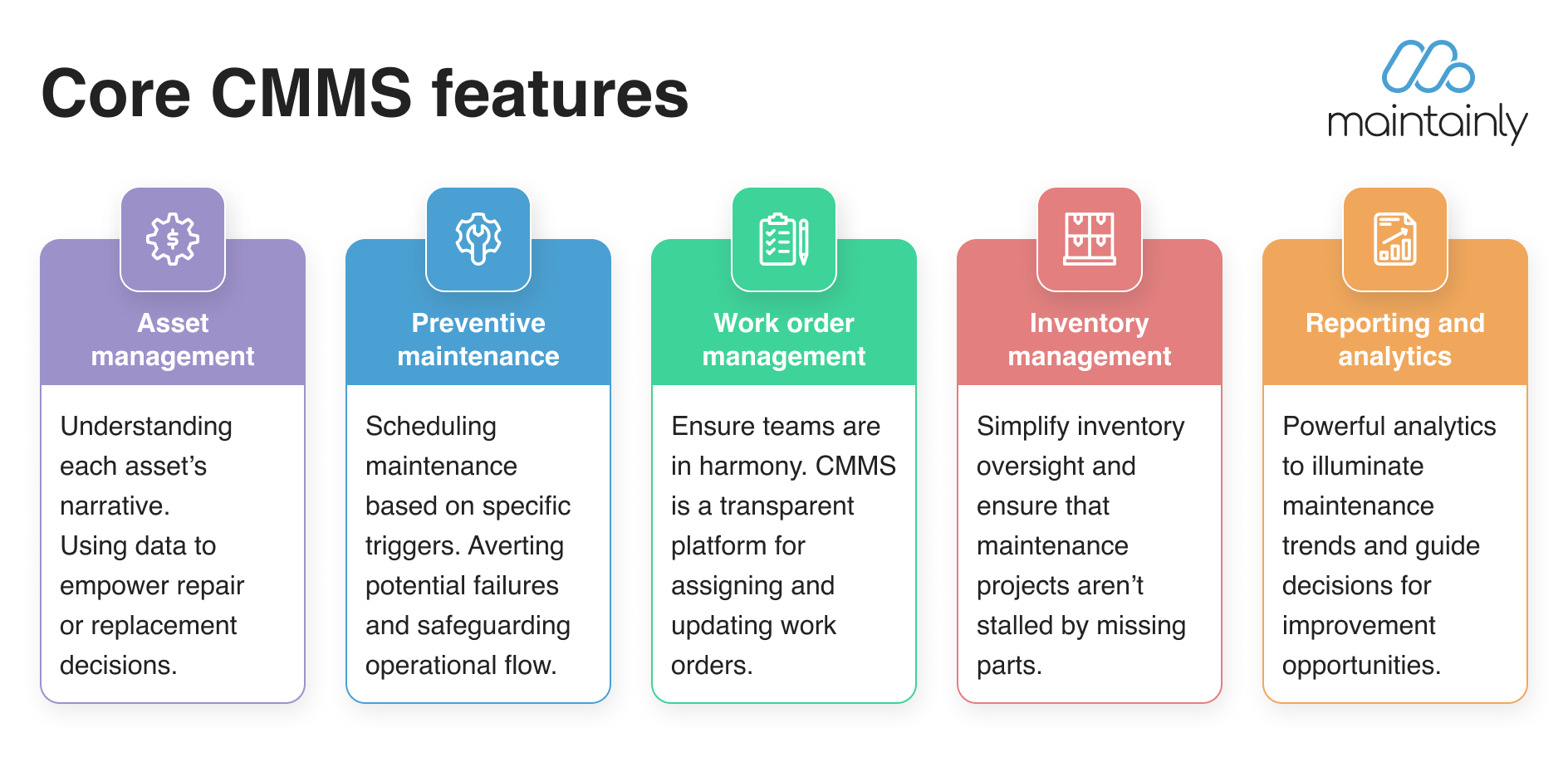

A Closer Look at the Core CMMS Features

Asset Management: CMMS isn't just about keeping track; it's about understanding each asset's narrative, from performance metrics to maintenance history, empowering decisions on repairs or replacements.

Preventive Maintenance: It champions a forward-thinking approach, scheduling maintenance activities based on specific triggers, thus averting potential failures and safeguarding operational flow.

Work Order Management: CMMS brings clarity and coordination to work orders, offering a transparent platform for assignments and updates, ensuring teams are in harmony.

Inventory Management simplifies inventory oversight, sends alerts when supplies run low, and ensures that maintenance projects aren't stalled by missing parts.

Reporting and Analytics: CMMS is equipped with powerful analytics, which illuminate maintenance trends and opportunities for improvement, guiding strategic decisions and resource planning.

The Broader Impact of CMMS

The ripple effect of integrating CMMS goes far beyond routine maintenance; it transforms maintenance departments from cost centers into pillars of strategic significance. CMMS plays a pivotal role in safety and operational efficiency by boosting asset reliability and ensuring compliance. The cost savings from reduced downtime and prolonged asset lifespan are substantial, while the insights garnered from CMMS analytics fuel continuous improvement and strategic foresight.

A Future Forward with Maintenance Software

To encapsulate, maintenance software, with CMMS at its heart, is indispensable for any organization looking to excel operationally. It heralds a structured, informed, and cost-efficient approach to maintenance management, keeping assets in prime condition and paving the way for future innovations. As we march into tomorrow, the evolution of CMMS promises even greater capabilities, ensuring businesses are well-equipped to tackle future challenges head-on.

This exploration of maintenance software and CMMS highlights their invaluable contribution to modern business strategies. By embracing these advanced tools, companies refine their maintenance processes and set the stage for broader operational enhancements, making an irrefutable case for their adoption.

Further Reading

What is CMMS?

A Computerized Maintenance Management System (CMMS) is a software solution that streamlines and automates maintenance management processes, including work orders, preventive maintenance, asset tracking, and inventory management, to optimize the efficiency and performance of organizational assets. But let's dig into the details...

Read more →