Preventative Maintenance Metric Readings have been Supercharged

Preventative Maintenance & Metric Readings

Monitoring metric readings on assets in a good CMMS can give valuable insights into equipment health, performance trends, and potential issues or anomalies that may indicate impending failures or maintenance needs.

Metrics can encompass various parameters such as temperature, pressure, vibration levels, fluid levels, energy consumption, odometer readings and more, depending on the type of asset and its operational requirements.

Metric readings are typically collected:

Manually during routine maintenance or corrective maintenance;

Via sensors, often connected to CMMS via an API, allowing for real-time monitoring and analysis of asset performance.

These insights enable proactive maintenance strategies, such as predictive maintenance, where maintenance activities are scheduled based on data-driven predictions of when assets are likely to require servicing or repairs. Ultimately, leveraging metric readings on assets helps optimize asset reliability, minimize downtime, and maximize operational efficiency.

Until today, there was a disconnect between Maintainly metric-based preventative maintenance and the automated triggers used for time-based preventative maintenance. Here's what we've done to address the relationship between metric readings and preventative maintenance.

Metric Readings are now Fully Integrated

We recently informed Maintainly users, and wrote about it here about how implementing Task Templates and Automations in Maintainly would dramatically streamline and simplify the process of adding, managing and even understanding complex preventative maintenance programs.

The metrics and metric readings functionality has now been fully integrated with Task Templates & Automations.

Creating a metric on an asset enlivens two possibilities:

Creating a metric on an asset enlivens two possibilities:

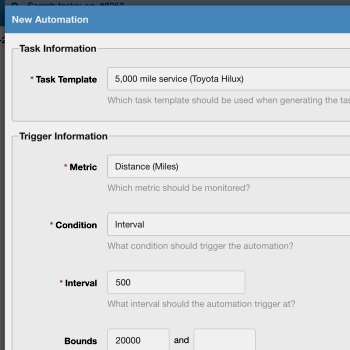

Set metric rules using Automations

Automations can be set up on the asset, establishing thresholds or rules relating to the metric, which then use the metric readings to trigger the generation of a task.

For example, if the temperature of a motor were to exceed a specified threshold, it may indicate overheating, which could lead to premature wear or failure of the motor bearings. By adding an Automation with thresholds that monitors the temperature readings when submitted, tasks can be generated automatically when the temperature is outside of the the predefined bounds. This allows your team to perform inspections and/or to address the issue before it escalates into a major failure.

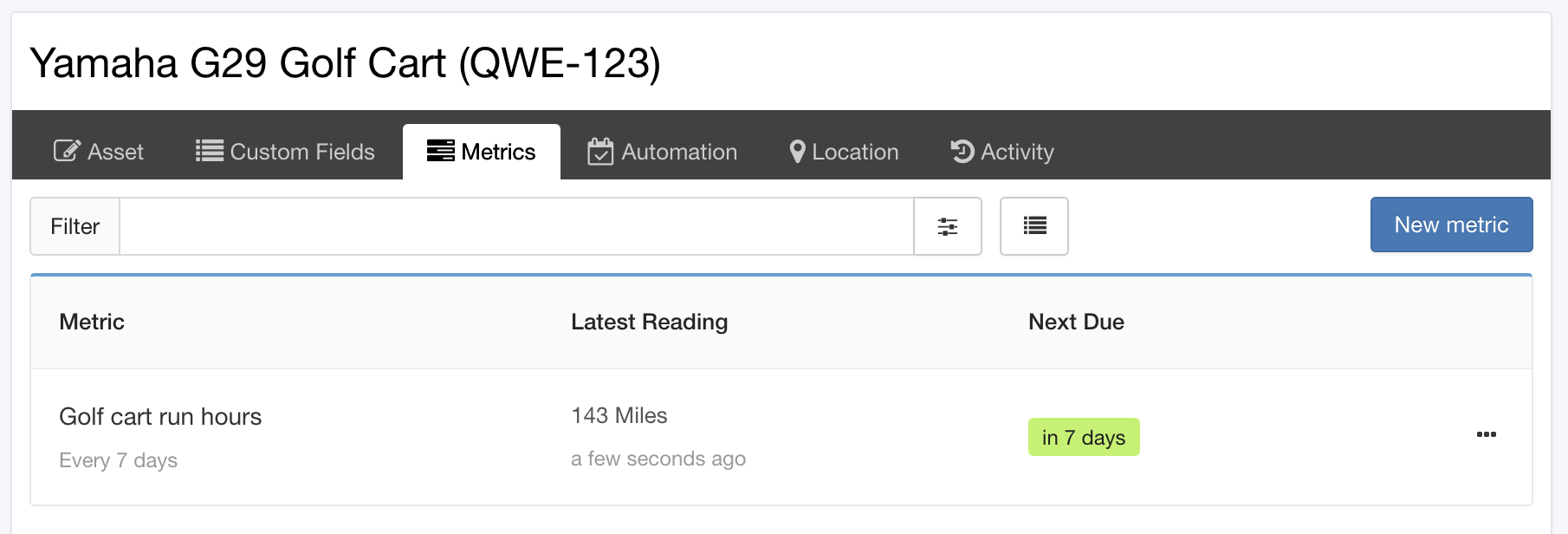

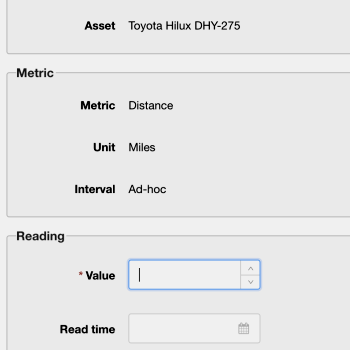

Submit metric readings

Readings of a metric on an asset can be taken and submitted on an ad-hoc basis, or on a pre-defined collection schedule, for analysis or simply recorded for historical purposes or, now, to trigger the creation of a task.

Metrics can be collected:

In any task

Directly on an asset

Via the new Metrics page

Whenever a metric reading in submitted, Maintainly will check that against the pre-defined rules and thresholds that you have established. If the metric reading meets the defined criteria, a corrective maintenance task will be created.

Check it out and let us know what you think!

Further Reading

What is CMMS?

A Computerized Maintenance Management System (CMMS) is a software solution that streamlines and automates maintenance management processes, including work orders, preventive maintenance, asset tracking, and inventory management, to optimize the efficiency and performance of organizational assets. But let's dig into the details...

Read more →

Benefits of CMMS

CMMS will aid and inform technicians out in the field, as well as decision makers, on maintenance work that has been done, will be done soon, or is planned to be done in the future. Broadly speaking, the benefits of CMMS can be broken down into three categories: management; visibility; and cost control.

Read more →

What is the 75% Maintenance Rule in Asset Management: When to Repair or Replace

What exactly is the 75% maintenance rule, how is it applied, and why should it be integrated into your Computerized Maintenance Management System (CMMS)?

Read more →