Work Order Fix Management for Manufacturing: Plan, Manage and Execute Facility Maintenance Efficiently

A Work Order Fix Management system is an essential tool for every manufacturing facility to plan, manage and execute facility maintenance efficiently. We will explore why such a system is crucial for manufacturing facilities, examining the benefits it offers in terms of safety, compliance, and overall operational efficiency and the overall impact on cost-effectiveness, and asset longevity.

Manufacturing Maintenance Costs

Implementing a Work Order Fix Management system helps manufacturing facilities reduce maintenance costs significantly. By streamlining maintenance processes, facilities can schedule repairs and preventive maintenance more effectively. This minimizes unplanned downtime, emergency repairs, and costly equipment failures. Moreover, the system enables facilities to better allocate resources, optimizing labor, spare parts inventory, and equipment usage, ultimately leading to cost savings.

Likewise, long-term costs are reduced by enhancing the asset longevity of any manufacturing facilities that rely heavily on their equipment and assets. A Work Order Fix Management system aids in extending the lifespan of these assets. Through regular preventive maintenance scheduling and timely repairs, facilities can ensure that their machinery and equipment remain in optimal working condition. This not only prevents unexpected breakdowns but also reduces the need for costly replacements, contributing to long-term cost savings.

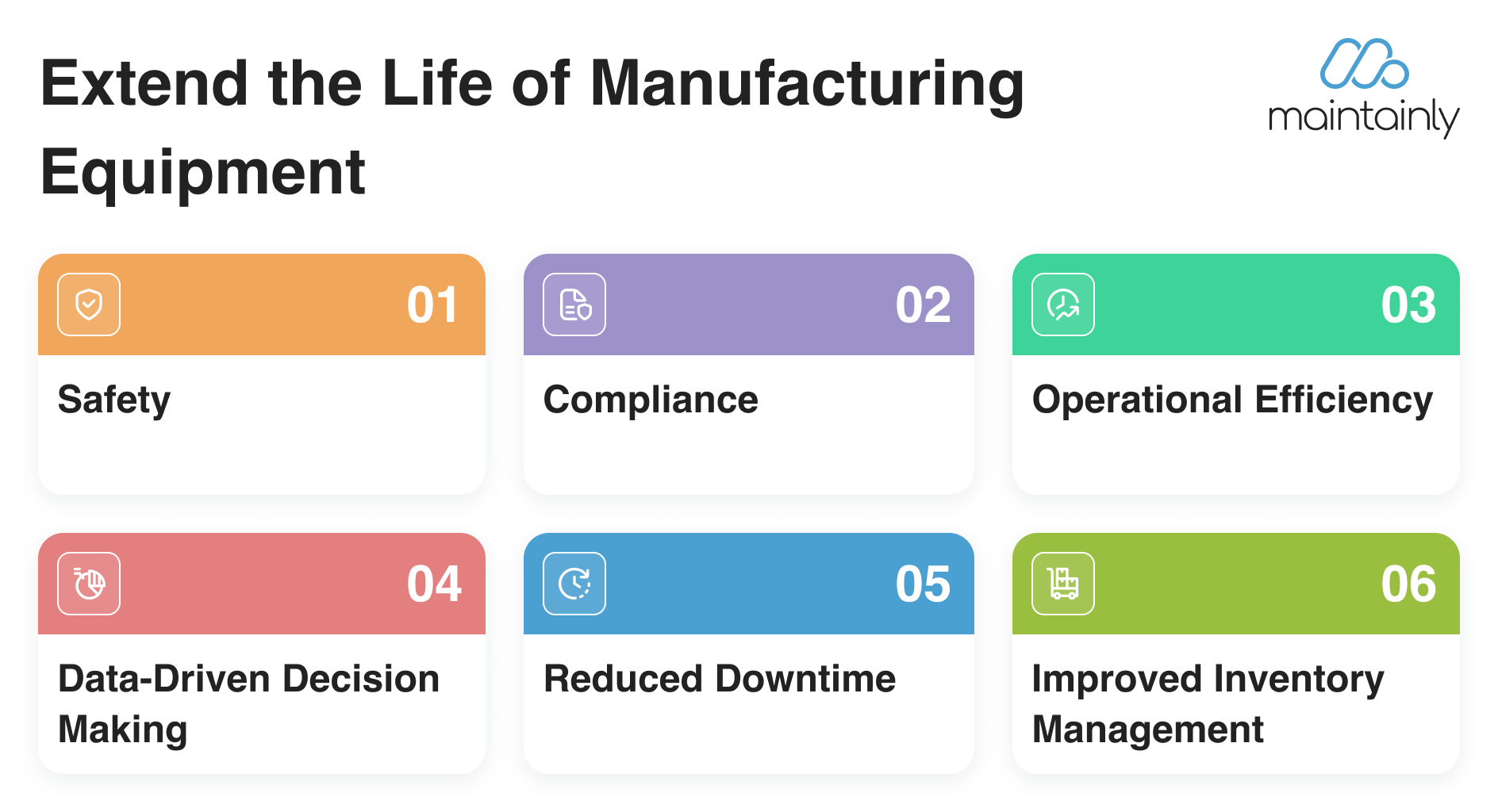

10 ways for manufacturing facilities to be cost-effective and extend the life of manufacturing equipment:

Safety

Safety is a top priority in manufacturing facilities, and effective maintenance plays a crucial role in ensuring a safe working environment. A Work Order Fix Management system helps identify and address safety issues promptly. Maintenance tasks related to safety can be prioritized and tracked more efficiently, reducing the risk of accidents and injuries. Furthermore, by keeping equipment in good working order, the system contributes to the overall safety of the facility.

Compliance

Manufacturing facilities often operate in highly regulated environments. Compliance with industry-specific regulations and standards is non-negotiable. A Work Order Fix Management system can assist in maintaining compliance by documenting all maintenance activities, providing an audit trail, and ensuring that equipment meets regulatory requirements. This helps facilities avoid fines, penalties, and legal issues related to non-compliance.

Operational Efficiency

Efficiency is key to the success of manufacturing operations. A Work Order Fix Management system enhances operational efficiency in several ways. It automates the scheduling of maintenance tasks, assigns them to the appropriate personnel, and tracks progress in real-time. This eliminates manual paperwork, reduces administrative overhead, and allows staff to focus on core tasks, thereby improving overall productivity.

Data-Driven Decision Making

A Work Order Fix Management system generates valuable data and insights about equipment performance and maintenance trends. By analyzing this data, facilities can make informed decisions regarding equipment upgrades, replacements, and maintenance strategies. This data-driven approach enables facilities to optimize their maintenance processes continually, leading to better resource allocation and cost control.

Reduced Downtime

Unplanned downtime can be extremely costly for manufacturing facilities. A Work Order Fix Management system helps reduce downtime by enabling predictive maintenance. By monitoring equipment condition and performance data, the system can predict when equipment is likely to fail and schedule maintenance before a breakdown occurs. This proactive approach minimizes production disruptions and associated financial losses.

Improved Inventory Management

Managing spare parts inventory efficiently is a significant challenge for manufacturing facilities. The Work Order Fix Management system can help facilities keep track of spare parts usage and availability. It ensures that the right parts are in stock when needed, reducing the time and cost associated with searching for and ordering parts during maintenance activities.

Enhanced Communication

Effective communication is essential for smooth maintenance operations. A Work Order Fix Management system provides a centralized platform for communication between maintenance teams, supervisors, and other stakeholders. This fosters collaboration, ensures that everyone is on the same page regarding maintenance priorities, and facilitates timely decision-making.

Historical Data and Documentation

Over time, a Work Order Fix Management system accumulates a comprehensive history of maintenance activities. This historical data is invaluable for analyzing trends, assessing the effectiveness of maintenance strategies, and making informed decisions about equipment maintenance, repairs, and replacements. It also serves as a valuable resource for training new staff and demonstrating compliance during audits.

Scalability and Flexibility

Manufacturing facilities often expand or adapt their operations over time. A good Work Order Fix Management system is scalable and flexible, allowing facilities to easily incorporate new equipment, processes, or locations into the maintenance workflow. This adaptability ensures that the system remains effective as the facility evolves.

Employee Satisfaction and Safety

Well-maintained equipment is not only safer but also easier and more enjoyable for employees to work with. A Work Order Fix Management system helps create a safer and more pleasant working environment, which can boost employee morale and reduce turnover.

A Work Order Fix Management system, like Maintainly, is indispensable for manufacturing facilities seeking to operate efficiently, cost-effectively, and safely. It not only helps reduce maintenance costs and extend the lifespan of assets but also ensures compliance with regulations, enhances operational efficiency and facilitates data-driven decision-making. By streamlining maintenance processes, reducing downtime, improving inventory management, and promoting better communication, this system becomes a critical tool for maintaining a competitive edge in today's manufacturing landscape. Furthermore, its scalability and adaptability make it an investment that can support a facility's growth and evolution over time. Overall, a Work Order Fix Management system is an essential component of modern manufacturing, providing the foundation for sustainable, safe, and successful operations.