The Power of Predictive Maintenance: A Comprehensive Guide

Understanding Predictive Maintenance

Predictive maintenance stands at the forefront of modern maintenance strategies, revolutionizing the way industries manage their assets. Unlike traditional reactive or scheduled approaches, predictive maintenance leverages advanced technologies and data analytics to anticipate potential equipment failures, allowing organizations to address issues before they lead to costly downtime. In this comprehensive guide, we will delve into the essence of predictive maintenance, exploring its definition, key components, benefits, and how it has become a game-changer for industries aiming for operational excellence.

Predictive maintenance is a proactive maintenance strategy that utilizes data analytics, sensors, and machine learning to predict when equipment is likely to fail. This approach shifts the maintenance paradigm from reactive, fix-as-fail practices to a more strategic, predictive model. By continuously monitoring equipment conditions and analyzing historical data, predictive maintenance algorithms can identify patterns and anomalies that indicate potential issues. This foresight empowers organizations to schedule maintenance activities precisely when they are needed, optimizing resources, reducing downtime, and extending the lifespan of critical assets.

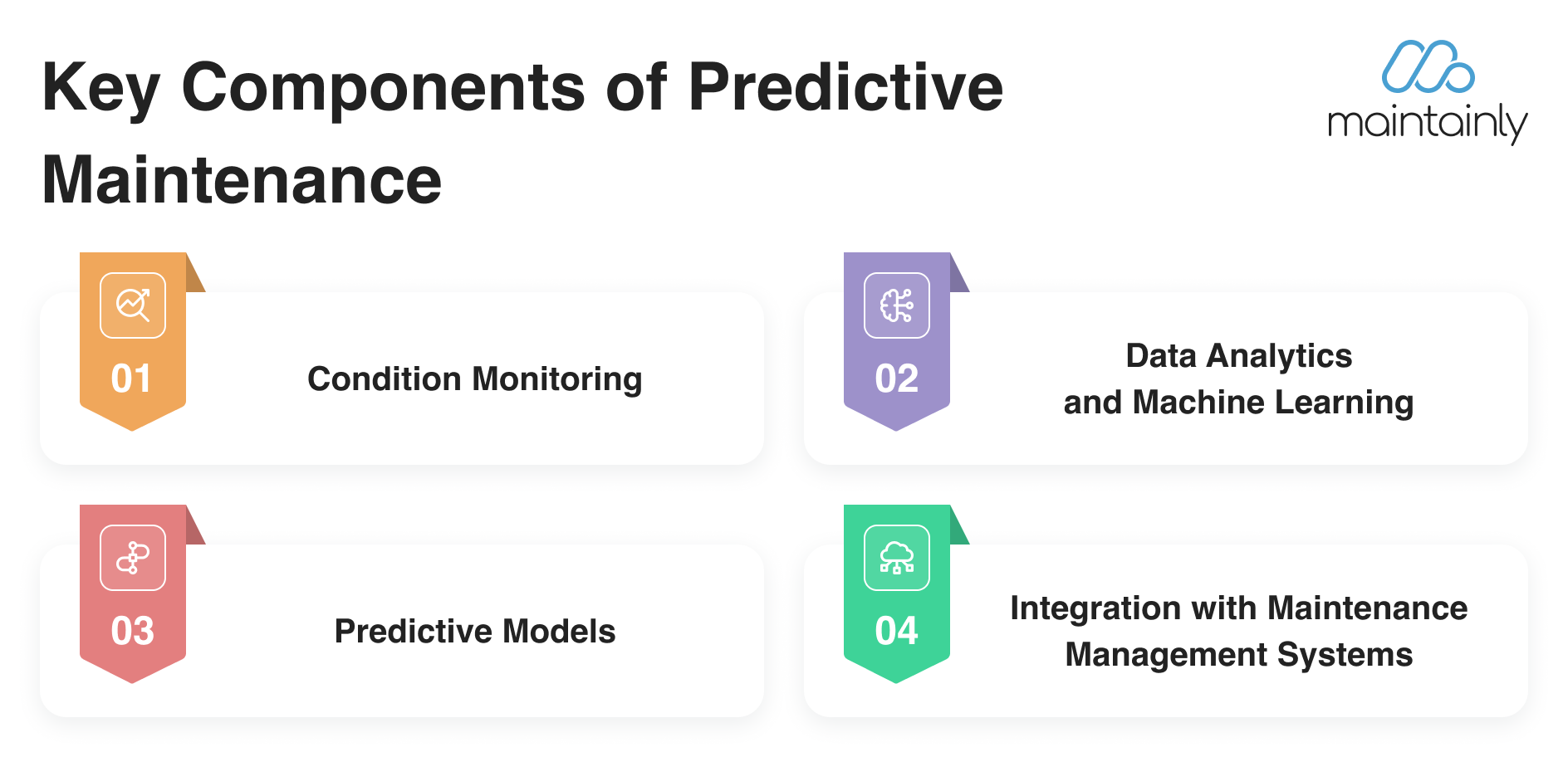

Key Components of Predictive Maintenance

Condition Monitoring

Central to predictive maintenance is the real-time monitoring of equipment conditions. Sensors and IoT devices are employed to collect data on factors such as temperature, vibration, pressure, and other performance metrics. This continuous stream of data provides insights into the health of assets and allows organizations to detect deviations from normal operating conditions.

Data Analytics and Machine Learning

Predictive maintenance relies heavily on advanced data analytics and machine learning algorithms. These technologies analyze large volumes of data to identify patterns, trends, and anomalies. Over time, the algorithms become more accurate in predicting potential failures, as they learn from historical data and adapt to evolving operational conditions.

Predictive Models

Organizations develop predictive models based on historical data, equipment specifications, and real-time monitoring. These models predict the remaining useful life of assets and anticipate when maintenance activities should be performed. Predictive models are continuously refined and improved as more data becomes available, enhancing their accuracy.

Integration with Maintenance Management Systems

Seamless integration with Computerized Maintenance Management Systems (CMMS) or sometimes even Enterprise Asset Management (EAM) systems can sometimes enhance the success of predictive maintenance. Integrating predictive maintenance data with these systems ensures that maintenance teams receive timely alerts, work orders are generated efficiently, and historical maintenance records are updated in real-time.

Benefits of Predictive Maintenance

Benefits of Predictive Maintenance

Minimized Downtime

Predictive maintenance allows organizations to address potential issues before they escalate into critical failures. By scheduling maintenance activities based on data-driven predictions, downtime is minimized, and production continuity is maintained.

Optimized Maintenance Resources

Resources are allocated more efficiently with predictive maintenance. Instead of following a fixed schedule, maintenance teams focus their efforts on equipment that genuinely requires attention. This optimization results in cost savings and increased overall operational efficiency.

Extended Asset Lifespan

Anticipating and addressing issues before they lead to breakdowns contributes to the extended lifespan of assets. Predictive maintenance ensures that equipment operates within optimal parameters, reducing wear and tear and prolonging overall asset life.

Cost Savings

The proactive nature of predictive maintenance translates to cost savings. Emergency repairs, overtime labor costs, and the expenses associated with unplanned downtime are significantly reduced, contributing to a more cost-effective maintenance strategy. Specifically costs savings can be achieved in the following key areas:

Reduced Downtime: As mentioned above, predictive maintenance helps to minimize unexpected equipment failures by identifying potential issues before they become serious. This reduces unplanned downtime, which can be very costly in terms of lost production and emergency repairs.

Extended Equipment Lifespan: Also addressed above, by addressing issues early and maintaining equipment in optimal condition, predictive maintenance can naturally lead to cost savings. This reduces the need for frequent replacements and the associated costs.

Optimized Maintenance Schedules: Traditional maintenance strategies, such as reactive (repairing after failure) or preventive (regularly scheduled maintenance regardless of condition), can be inefficient. Predictive maintenance allows for maintenance activities to be performed only when necessary, based on actual equipment condition and performance data. This reduces unnecessary maintenance activities and associated labor costs.

Reduced Spare Parts Inventory: With predictive maintenance, there is better forecasting of when parts will be needed, reducing the need to keep a large inventory of spare parts on hand. This cuts down on inventory holding costs and reduces capital tied up in unused parts.

Lower Energy Costs: Equipment that is properly maintained operates more efficiently, consuming less energy. Predictive maintenance ensures that machines run at their optimal performance levels, leading to lower energy consumption and costs.

Improved Safety: Predictive maintenance can identify and rectify potential safety hazards before they cause accidents. This reduces costs related to workplace injuries, insurance claims, and regulatory fines.

Data-Driven Decisions: Predictive maintenance relies on data analytics and monitoring technologies, providing valuable insights into equipment performance and maintenance needs. This data-driven approach allows for more accurate budgeting and resource allocation, avoiding unnecessary expenditures.

Reduction in Emergency Repairs: Emergency repairs are typically more expensive than planned maintenance due to overtime labor, rush shipping for parts, and potential collateral damage from unexpected failures. Predictive maintenance helps to avoid these costs by allowing for planned, timely interventions.

Enhanced Safety and Reliability

Predictive maintenance enhances workplace safety by addressing potential safety hazards before they become critical. Moreover, the reliability of equipment is improved, fostering a safer and more productive working environment.

Predictive maintenance represents a transformative shift in the maintenance landscape, offering organizations a proactive and data-driven approach to asset management. By harnessing the power of condition monitoring, data analytics, and predictive models, industries can optimize their maintenance practices, minimize downtime, and achieve operational excellence. As technology continues to advance, predictive maintenance stands as a beacon of efficiency, guiding organizations towards a future where equipment failures are anticipated and addressed before they impact the bottom line. Embracing predictive maintenance is not just a strategic choice; it is a commitment to a smarter, more resilient, and future-ready approach to maintenance management.