Compliance & the Role of Maintenance Management Software

Compliance & the Role of Maintenance Management Software

Compliance is increasingly central in today’s business environment, especially in industries like manufacturing, healthcare, energy, and transportation, where regulations are stringent and complex. To maintain adherence to these rules, companies use a range of tools, with maintenance management software playing a vital role in ensuring operational compliance and efficiency. Maintenance management software, often referred to as Computerized Maintenance Management Software (CMMS), facilitates compliance by managing equipment, scheduling inspections, automating documentation, and providing data analytics. This post explores how CMMS supports compliance efforts and helps companies streamline maintenance management, reduce risks, and achieve operational excellence.

Understanding Compliance in Maintenance

Compliance in maintenance refers to adhering to industry regulations, safety standards, environmental guidelines, and company policies that dictate how equipment should be maintained, monitored, and documented. Regulatory bodies, such as the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) in the United States, outline requirements that companies must follow to ensure worker safety, environmental protection, and reliable equipment operation.

Compliance requirements vary across industries, but they generally include:

Regular Inspections and Maintenance: Ensuring that equipment is inspected and serviced at specified intervals to avoid malfunctions.

Record-Keeping: Documenting maintenance activities, repairs, and inspections to verify compliance and trace any issues that arise.

Safety Protocols: Implementing procedures that protect employees and customers, especially when operating complex machinery.

Environmental Standards: Complying with regulations regarding waste, emissions, and hazardous materials.

Failure to meet these standards can result in fines, penalties, legal action, or severe reputational damage. Maintenance management software helps organizations navigate these requirements efficiently.

How Maintenance Management Software Supports Compliance

How Maintenance Management Software Supports Compliance

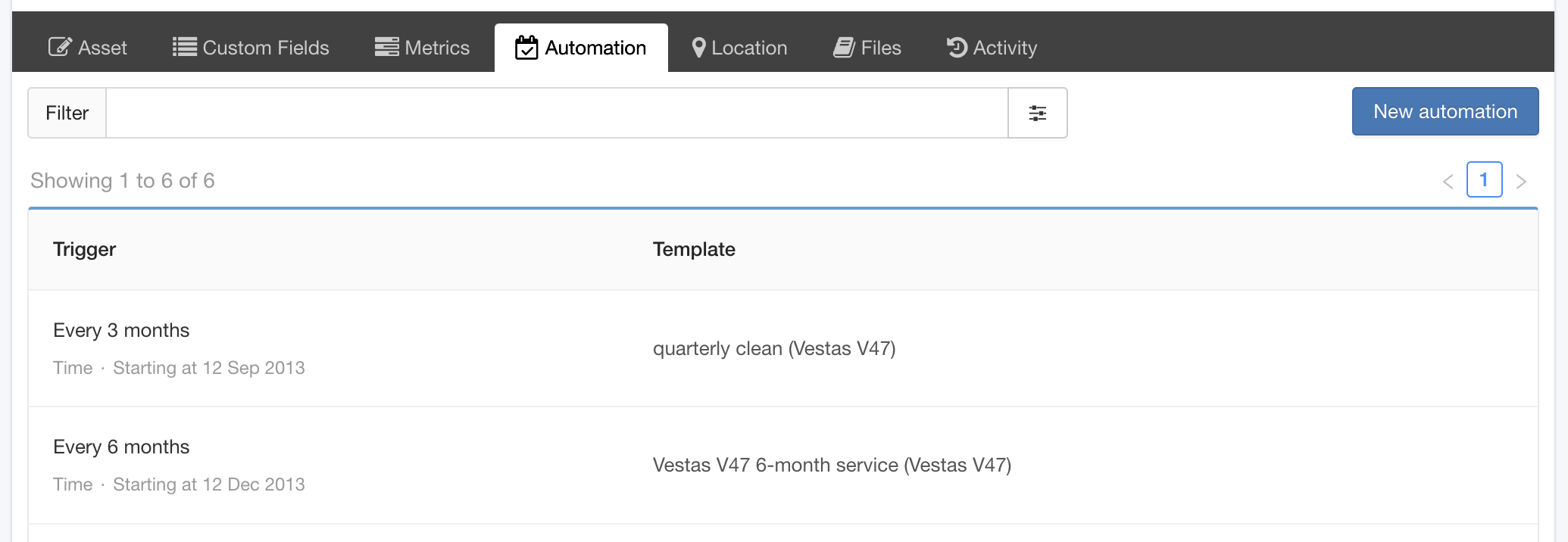

1. Automated Scheduling and Preventive Maintenance

CMMS systems enable preventive maintenance by automating scheduling for equipment inspections, calibrations, and routine maintenance. By doing so, companies can avoid downtime due to unexpected failures and ensure that equipment consistently meets regulatory standards. For example, scheduling features in CMMS allow users to set up reminders for regulatory compliance deadlines, such as OSHA inspections or EPA emissions checks. Automating these processes reduces human error and ensures that all tasks are completed on time.

2. Improved Documentation and Record-Keeping

2. Improved Documentation and Record-Keeping

Record-keeping is a critical component of regulatory compliance, particularly for demonstrating compliance during audits. Maintenance management software facilitates this by automatically tracking and storing data on each maintenance task performed, including:

Date and time of the maintenance or inspection.

Name of the technician or inspector.

Specific actions taken and parts replaced.

Digital signatures and photographic evidence when required.

This centralized documentation helps businesses produce necessary records quickly for audits and regulatory checks, simplifying compliance and reducing the risk of penalties due to missing or incomplete records. By maintaining a digital log of all maintenance activities, companies can also track and analyze their performance trends over time.

3. Compliance Reporting and Auditing Tools

Maintenance management software typically includes reporting tools that allow users to generate customized compliance reports. These reports provide insights into maintenance schedules, equipment performance, and adherence to regulatory standards. For example, CMMS can generate reports on:

Scheduled vs. completed maintenance tasks.

Safety inspections and outcomes.

Asset health and lifecycle information.

These reports are valuable during audits as they offer a clear record of compliance activities. Moreover, many CMMS platforms have audit trail features that track user actions within the system, providing transparency and accountability.

4. Risk Management and Safety Protocols

One of the core goals of compliance is to minimize risks to both people and equipment. CMMS helps enforce safety protocols by ensuring that all equipment is maintained according to manufacturer guidelines and regulatory standards. The software can store safety protocols and standard operating procedures, making them easily accessible to technicians. This feature helps companies stay compliant with occupational safety standards and enhances workplace safety by ensuring that everyone follows the correct procedures.

Additionally, maintenance management software can trigger alerts if an asset fails or if there’s a need for immediate inspection. This proactive approach reduces the risk of accidents and equipment failure, both of which could result in regulatory violations.

5. Data Analytics and Predictive Maintenance

CMMS can help companies move beyond preventive maintenance into predictive maintenance, which uses data to predict potential failures before they happen. This predictive approach leverages sensors and the Internet of Things (IoT) to monitor equipment performance in real-time, providing insights that allow maintenance teams to address issues before they escalate into compliance problems.

For example, vibration or temperature sensors on a piece of equipment can alert maintenance teams if the equipment is at risk of failing. By addressing these issues proactively, companies can prevent unexpected breakdowns that might lead to regulatory non-compliance, fines, or safety hazards.

6. Environmental Compliance

In industries with significant environmental impact, such as manufacturing or energy, environmental compliance is a key focus. Maintenance management software can assist by tracking environmental metrics, such as emissions or waste output, and ensuring that equipment is operating within legal parameters. For instance, the software can log data on emissions levels, energy usage, and waste disposal methods, helping companies ensure that they meet EPA guidelines or other environmental regulations.

Real-World Applications

The benefits of maintenance management software for compliance can be seen across various sectors:

Healthcare: Hospitals use CMMS to maintain medical equipment according to stringent safety standards, such as those set by the FDA. CMMS helps ensure that critical equipment like MRI machines and ventilators are regularly inspected and maintained.

Manufacturing: Manufacturers rely on CMMS to keep production equipment in optimal condition, which helps prevent accidents and minimize downtime, ultimately ensuring compliance with OSHA and industry-specific regulations.

Utilities and Energy: Power plants and other utility companies use CMMS to monitor their equipment’s environmental impact, ensuring compliance with emissions regulations and reducing environmental risks.

Choosing the Right CMMS for Compliance

When selecting maintenance management software, it’s important to consider features that specifically support compliance, such as:

Customizable Reporting Tools: Look for software that allows you to generate specific compliance reports.

Audit Trail Capabilities: Ensure that the software records user actions for accountability and transparency.

Mobile Access: Mobile capabilities are essential for technicians to access maintenance records, protocols, and reporting features while on-site.

Integration with IoT Sensors: IoT-enabled CMMS offers predictive maintenance features that enhance compliance through proactive issue management.

Compliance & CMMS

Compliance is an essential but complex aspect of managing modern industrial facilities. Maintenance management software simplifies compliance by streamlining processes, improving documentation, and reducing the risk of regulatory infractions. CMMS tools can support preventive and predictive maintenance efforts, aid in environmental compliance, and enhance workplace safety, ensuring that companies remain competitive and compliant. With the right maintenance management software, businesses can protect their assets, ensure safety, and maintain a proactive approach to regulatory adherence.