Mobile menu

Manufacturing & Plants

Let's empower your manufacturing and plant operations with knowledge for seamless work order management and drive productivity to new heights. From manufacturing plants to production facilities, our expert-curated content offers valuable insights to streamline workflows, minimize downtime, and enhance operational efficiency. Stay updated on the latest trends and practical tips to harness the power of maintenance software effectively.

← Back

Navigating Free CMMS: Understanding Variations and Choosing the Right One for Your Business

While there are numerous paid CMMS options available, the market also offers a variety of free CMMS solutions. However, not all free CMMS platforms are created equal.

View article →

What is Maintenance Software?

This sophisticated tool suite is reshaping how businesses maintain their assets, promising safety, enhanced longevity, and maximum productivity.

View article →

The Power of CMMS Software: Revolutionizing Work Order Management

CMMS software has transformed how businesses manage and execute maintenance tasks, bringing about unparalleled efficiency and accuracy in work order management.

View article →

Why Preventive Maintenance Reduces Asset Downtime and Boosts Efficiency

Preventive maintenance is a proactive approach to asset management that involves scheduled inspections, repairs, and upkeep to prevent equipment failures and unplanned downtime. This strategic maintenance methodology aims to identify and address potential issues before they escalate, ensuring that assets operate at peak efficiency.

View article →

Simplifying Maintenance Management: Why Simple CMMS is Ideal for SMEs

While legacy Computerized Maintenance Management Systems (CMMS) have been the traditional choice for many organizations, the emergence of simple CMMS solutions offers a compelling alternative.

View article →

How CMMS Software Boosts Preventive Maintenance Strategies

By integrating advanced technology with maintenance operations, CMMS platforms have become indispensable tools for optimizing asset management and ensuring operational continuity.

View article →

Demystifying CMMS Maintenance Terms: Understanding PMs, CM, Reactive, and Corrective Maintenance

Navigating through the plethora of CMMS terminologies can be akin to deciphering a complex code. From Preventive Maintenance (PM) to Corrective Maintenance (CM), and Reactive Maintenance to Condition-Based Maintenance, each term carries specific nuances that play a pivotal role in the efficient functioning of an organization and maintain software.

View article →

Simplify and Streamline: How CMMS Systems Enhance Work Order Efficiency

Computerized Maintenance Management Systems, or CMMS, offer a digital solution to manage all aspects of maintenance operations, proving essential for organizations aiming to boost efficiency, reduce costs, and ensure the longevity of their assets. This article delves into the core advantages of integrating CMMS into your maintenance strategy and explores how it reshapes work order management.

View article →

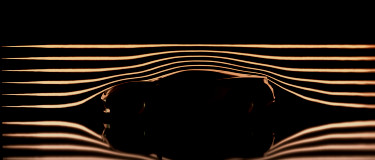

The Power of Predictive Maintenance: A Comprehensive Guide

Predictive maintenance stands at the forefront of modern maintenance strategies, revolutionizing the way industries manage their assets. Unlike traditional reactive or scheduled approaches, predictive maintenance leverages advanced technologies and data analytics to anticipate potential equipment failures, allowing organizations to address issues before they lead to costly downtime.

View article →

Unraveling Maintenance Mysteries: The Role of Root Cause Analysis in CMMS

The quest for operational excellence involves not just fixing issues as they arise but understanding why they occurred in the first place. Root Cause Analysis (RCA) emerges as a crucial tool in this pursuit, unraveling the mysteries behind equipment failures and operational disruptions.

View article →