Mobile menu

Manufacturing & Plants

Let's empower your manufacturing and plant operations with knowledge for seamless work order management and drive productivity to new heights. From manufacturing plants to production facilities, our expert-curated content offers valuable insights to streamline workflows, minimize downtime, and enhance operational efficiency. Stay updated on the latest trends and practical tips to harness the power of maintenance software effectively.

← Back

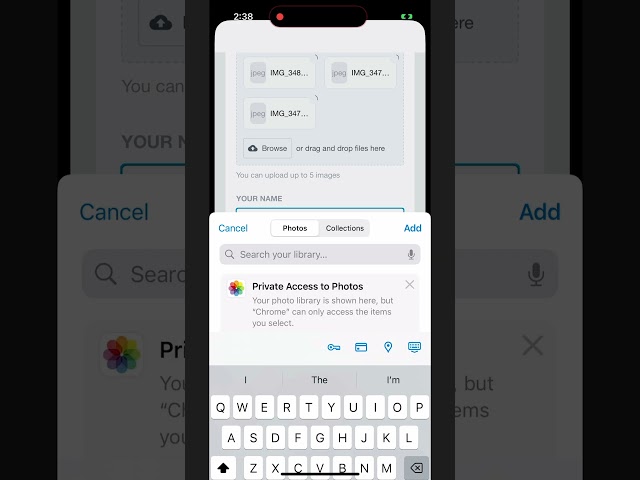

Image Uploads on Maintenance Requests

From small maintenance teams to enterprise-scale operations, visual documentation is often the missing link between a fast fix and frustrating downtime. By enabling users to upload images directly when submitting a maintenance request, we’re bridging that gap.

View article →

Why Preventative Maintenance Software Is a Game-Changer for Small Businesses

Preventative maintenance software can be one of the smartest investments a small business can make. Rather than adding unnecessary administrative burden, it streamlines operations, saves time, reduces costs, and increases efficiency across the board.

View article →

Understanding the Maintenance Process: A Deep Dive into Efficiency and Reliability

Whether you manage a facility, oversee a production floor, or operate a small business, understanding the maintenance process can empower you to minimize downtime, extend asset lifespan, and improve operational efficiency.

View article →

Introducing Our New & Improved File Uploader for CMMS

We’re excited to introduce our brand-new file uploader tool in our CMMS software! This update brings significant improvements in speed, security, and usability, making CMMS file management easier than ever for maintenance teams.

View article →

Video: Maintainly Set-up Guide

April 2025 update video on getting started in Maintainly. We take a look at the initial basics to get you started on the right foot!

View article →

CMMS Boosts Sustainability

Not only can CMMS help you organize, maintain, and track your assets, but it can also improve your business sustainability goals. In this blog, we’ll highlight how a CMMS can be a pivotal tool to help your business achieve sustainability.

View article →

CMMS Simplifies Inventory Management

Whether you're managing a small team or overseeing a large facility with thousands of assets, staying on top of your inventory can make the difference between smooth operations and costly downtime.

View article →

Facility Management and CMMS

Let’s take an in-depth look at how a CMMS like Maintainly revolutionizes facility management and why it’s become indispensable for facility maintenance teams of all sizes.

View article →

What Industries Benefit From CMMS?

Businesses of all sizes rely on CMMS for accurate asset management. If you have a large inventory, production equipment or a fleet of vehicles then you can benefit from CMMS.

View article →

Challenging Existing CMMS Processes: A Rigid Framework for Efficiency

A truly effective CMMS should actively challenge the status quo, guiding organizations toward best practices to streamline operations and improve efficiency.

View article →