Audit Trails and CMMS: Accuracy, Reliability, and Compliance in Maintenance Management

Where efficiency, compliance, and accountability are paramount, audit trails play a critical role in how organizations monitor, record, and validate their operations. Whether it is in hospitality, healthcare, manufacturing, or facilities management, audit trails provide the proof and transparency necessary to ensure that actions are properly recorded, decisions can be validated, and compliance obligations are met. For maintenance teams, a Computerized Maintenance Management System (CMMS) offers a streamlined and powerful solution to create and maintain accurate audit trails that support troubleshooting, prediction, and compliance.

This article explores what audit trails are, why they are so important, and how CMMS software empowers maintenance teams to build reliable systems that future-proof operations.

What is an Audit Trail?

An audit trail is a chronological record of events, activities, or transactions that provides documented evidence of the sequence and details of a process. In simple terms, it is a “paper trail” or “digital footprint” that shows what happened, when it happened, and who was involved. Audit trails can exist in many forms:

Financial Systems: Logs of every transaction, from purchase orders to approvals and payments.

Healthcare Systems: Records of patient interactions, test results, or medication administration.

Manufacturing or Maintenance Systems: Documentation of equipment repairs, preventive maintenance tasks, or inspections.

The purpose of an audit trail is not just to create records, but to ensure that those records can be trusted. By capturing details like timestamps, user actions, and modifications, organizations can have a clear, verifiable view of their operations.

Why Audit Trails Are Important

Audit trails serve several critical functions across industries:

1. Accountability and Transparency

An audit trail ensures that actions can be traced back to the responsible individual or department. This accountability discourages negligence and promotes transparency, which is essential in industries with regulatory oversight.

2. Error Detection and Troubleshooting

When issues arise, an audit trail can be invaluable in identifying the root cause. For instance, if a machine fails, maintenance teams can look back at the audit trail to see what maintenance was performed, when it was completed, and whether any issues were noted during inspections.

3. Regulatory Compliance

Many industries—such as healthcare, food production, and aviation, are subject to strict compliance requirements. Regulators often require organizations to produce reliable records showing maintenance schedules, inspection histories, and corrective actions. A well-maintained audit trail ensures compliance with these standards.

4. Operational Efficiency

Audit trails reduce the guesswork in decision-making. By providing accurate historical data, they allow managers to evaluate performance, predict issues, and make better-informed decisions about resources and scheduling.

5. Security and Fraud Prevention

Audit trails also serve as safeguards against fraudulent activity. If an irregularity is detected, audit logs can highlight unauthorized access, improper changes, or skipped steps.

Challenges with Manual Audit Trails

Traditionally, many organizations relied on paper logs, spreadsheets, or informal reporting to maintain audit trails. While these methods may capture basic records, they are fraught with challenges:

Human Error: Handwritten notes or spreadsheet entries can be incomplete or incorrect.

Inconsistency: Without standardized processes, data may vary across teams or sites.

Time-Consuming: Collecting, storing, and retrieving manual records is slow and inefficient.

Limited Security: Paper logs can be altered or lost, while spreadsheets may lack proper access controls.

Poor Scalability: As organizations grow, manual systems simply cannot keep up with the volume and complexity of data.

This is where a CMMS comes into play, offering a digital, centralized, and automated solution.

CMMS: The Key to Reliable Audit Trails

A Computerized Maintenance Management System (CMMS) is designed to organize, track, and optimize maintenance activities. At its core, a CMMS automates the process of recording and documenting maintenance tasks, creating accurate and tamper-resistant audit trails. Here’s how CMMS strengthens audit trail management:

1. Automated Data Capture

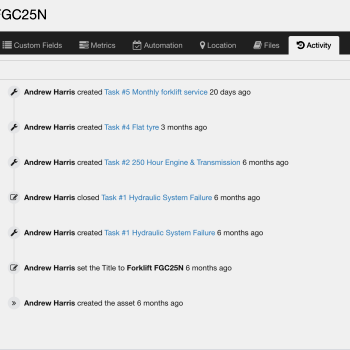

Every time a technician logs into the system, completes a work order, updates an inspection, or adds notes, the CMMS automatically records the action with a timestamp and user ID. This ensures that records are precise and complete.

2. Centralized Record-Keeping

Instead of scattered spreadsheets or paper binders, all maintenance records are stored in one centralized database. This makes retrieval fast, consistent, and secure.

3. User Accountability

With role-based permissions, a CMMS ensures that each user’s actions are recorded under their account. This makes it clear who completed tasks, approved actions, or made changes.

4. Integration with Assets

Audit trails in a CMMS are linked directly to assets. This means every machine or piece of equipment has a digital history that includes inspections, repairs, and preventive maintenance activities.

5. Security and Compliance

CMMS systems often include features like access controls, digital signatures, and compliance reporting. These features prevent tampering and make it easier to generate reports for audits or inspections.

Benefits of CMMS Audit Trails

By providing accurate and reliable audit trails, CMMS software enhances maintenance management in several key ways:

1. Troubleshooting

When equipment fails, maintenance teams need to act quickly to minimize downtime. CMMS audit trails provide a detailed history of the asset, showing what work has been done, which parts have been replaced, and any recurring issues. This history enables technicians to troubleshoot problems more effectively and avoid repeating past mistakes.

2. Predictive Maintenance

Audit trails provide the historical data that predictive maintenance relies on. By analyzing past maintenance records, organizations can identify patterns that signal potential failures. For example, if an air compressor requires a specific part replacement every six months, the CMMS audit trail highlights this trend, allowing the team to replace the part proactively before failure occurs.

3. Compliance and Reporting

For industries subject to compliance regulations, CMMS audit trails simplify reporting. When regulators ask for proof of maintenance schedules, safety inspections, or corrective actions, organizations can quickly generate detailed reports from the CMMS. This not only saves time but also builds confidence with auditors and clients.

4. Continuous Improvement

Audit trails aren’t just for compliance—they also fuel continuous improvement. By analyzing the data, maintenance managers can identify inefficiencies, optimize preventive maintenance schedules, and make data-driven decisions that improve performance.

Real-World Example: CMMS in Action

Consider a food processing plant where equipment downtime can cause significant production losses and even compliance violations. Before adopting a CMMS, the maintenance team relied on handwritten logs to record work. When auditors requested maintenance history, staff had to sift through binders of inconsistent notes, wasting valuable time.

After implementing a CMMS, every work order and inspection is logged digitally. Technicians use mobile devices to update tasks on the spot, and audit trails are automatically generated. When regulators arrive for an inspection, the plant manager can instantly produce reports showing preventive maintenance compliance, safety checks, and corrective actions taken. Not only does this save time, but it also improves the plant’s compliance rating and reduces the risk of costly fines.

Future-Proofing with CMMS Audit Trails

As organizations adopt new technologies such as IoT sensors, predictive analytics, and AI-driven maintenance planning, the role of audit trails will only grow more important. Accurate, digital records will serve as the foundation for these innovations. A CMMS ensures that organizations are not just keeping up with compliance, but are also positioned for future advancements.

For example, IoT-enabled equipment can feed performance data directly into a CMMS, creating audit trails that reflect real-time usage and condition. Predictive algorithms can then use that data to forecast failures with even greater accuracy, while still maintaining the reliability and compliance benefits of traditional audit trails.

The Backbone of Accountability

Audit trails are the backbone of accountability, compliance, and operational efficiency. They provide the transparency and reliability organizations need to operate effectively and meet regulatory demands. However, manual methods of tracking maintenance activities are no longer sufficient in today’s complex and fast-moving environments.

By adopting a CMMS, organizations can streamline audit trail management, ensuring that records are accurate, secure, and easily accessible. From troubleshooting equipment failures to predicting maintenance needs and passing compliance audits with ease, CMMS audit trails empower maintenance teams to build systems they can rely on well into the future.

In short, audit trails are not just a compliance checkbox, they are a strategic tool for reliability and growth. And with Maintainly CMMS, they become more powerful, more accurate, and more indispensable than ever.