Mobile menu

Energy & Utilities

Let's empower your operations with knowledge for seamless work order management and drive success in the energy and utility sector. From power plant maintenance to utility equipment upkeep, our expert-curated content offers valuable insights to streamline workflows, minimize downtime, and enhance productivity. Stay updated on the latest trends and practical tips to harness the power of maintenance software effectively.

← Back

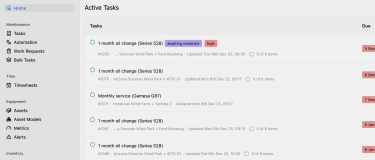

A Complete Breakdown of the New UI Features and Functional Improvements in Maintainly CMMS

Modern maintenance teams don’t just need more features. They need software that feels fast, clear, and EASY TO USE every single day. That’s exactly why Maintainly rolled out its brand-new UI. It is a functional upgrade designed around how maintenance work actually happens.

View article →

From Spreadsheets to Software: A Step-by-Step Guide to Migrating to CMMS

For years, spreadsheets have been the go-to tool for managing maintenance tasks. They’re familiar, flexible, and easy to set up. But as operations grow, spreadsheets start showing their limits. It could be missed work orders, outdated asset data, version confusion, or hours lost chasing information.

View article →

Introducing Maintainly’s Brand-New UI: Faster, Cleaner, and Built for the Future

Maintainly’s brand-new UI is here! Enjoy a cleaner, faster interface with smarter workflows and the foundation for exciting future CMMS features.

View article →

Why CMMS Adoption Fails and How to Ensure a Smooth Roll-Out

You’ve heard the promises: better preventive maintenance, fewer breakdowns, smooth work order flow, accurate asset history, and data you can finally trust. But how do you make the rollout a success?

View article →

Budgeting & ROI: Calculating the Financial Benefits of CMMS Implementation

Whether you’re maintaining manufacturing equipment, facilities, fleets, hotels or property assets, the way you maintain them directly affects productivity, safety, and profitability. Yet one of the most common questions we hear from maintenance leaders is "How do I justify the cost of CMMS as an essential tool?"

View article →

For Small & Medium Business CMMS, Maintainly is the Top Choice for 2026

We review a handful of the top CMMS options you’ll see on shortlists in 2026 and explain why, for teams in the sweet spot of 5–50 regular users, Maintainly is the best choice: fast onboarding, low friction for adopters, and pricing that scales sensibly for small & mid-sized companies.

View article →

Future Trends in Maintenance Management: What's Next for CMMS Software?

Maintenance management is changing faster than ever. With new technologies, smarter equipment, tighter budgets, and higher expectations for uptime, maintenance teams are rethinking how they work. And at the center of all this change is CMMS software - once a clunky, confusing tool, now becoming the backbone of modern operations.

View article →

Q&A with Patrick O’Meara, Founder of Maintainly: Rethinking CMMS for Modern Maintenance Teams

We sat down with Maintainly founder Patrick O’Meara to talk about how the platform started, what makes it different, and how it’s helping organizations bring preventive maintenance and asset management into the modern age.

View article →

The Science Behind Mobile CMMS Software: How It Tracks Equipment in Real Time

We all know how a little downtime can affect certain industries like manufacturing, healthcare, and IT, as even a 5s downtime can cost a lot. So, it’s very important to have the ability to monitor and maintain equipment efficiently.

View article →

How Mobile CMMS Software is Redefining Maintenance Management

The way maintenance teams work has changed more in the past five years than in the previous fifty. For decades, maintenance management meant clipboards, spreadsheets, and endless phone calls. Today, modern teams are leaving those headaches behind and moving toward a faster, smarter way of managing assets and work orders.

View article →